Ukugaya yindlela yokusika i-workpiece kwi-grinder kunye nevili lokugaya njengesixhobo sokusika.

Iimpawu zale ndlela zilandelayo:

1. Ngenxa yobunzima obuphezulu kunye nokumelana nokushisa kwee-abrasives zevili lokugaya, ukugaya kunokusebenza izinto ezinobunzima obuphezulu, njengentsimbi eqinile, i-carbide ene-cemented, njl.

2. Iimpawu zevili lokugaya kunye nomatshini wokugaya zinquma ukuba inkqubo yenkqubo yokugaya ingasetyenziselwa njenge-micro-cutting efanayo, ngokubanzi i-ap=0.001 ~ 0.005mm;isantya sokusila siphezulu kakhulu, ngokubanzi ukuya kuthi ga kwi-v=30 ~ 50m/s;umatshini wokugaya unokuqina okulungileyo;ukuhanjiswa kwe-hydraulic kusetyenziswa, ngoko ukugaya kunokufumana ukuchaneka okuphezulu kokucubungula (IT6 ~ IT5) kunye nobunzima obuncinane bomhlaba (Ra = 0.8 ~ 0.2um).Ukugaya yenye yeendlela eziphambili zokulungiswa kwamalungu.

3. Iqondo lokushisa kwindawo yokusila liphezulu kakhulu ngenxa yokuxhatshazwa okukhulu.Oku kuya kubangela uxinzelelo kunye nokuguqulwa kwe-workpiece, kwaye kubangele ukutshiswa komphezulu we-workpiece.Ngoko ke, isixa esikhulu sokupholisa kufuneka sitofwe kwinkqubo yokusila ukunciphisa ubushushu bokugaya.Isipholisi sikwasebenza njengokususwa kwetshiphu kunye nokuthambisa

4. I-radial force ngexesha lokugaya inkulu kakhulu.Oku kuya kubangela unikezelo olulastiki lwesixokelelwano somatshini wokugaya isixhobo sevili, ukuze ubunzulu bokwenyani bokusikiwe bungaphantsi kobunzulu obuqhelekileyo.Ngoko ke, xa ukugaya sele kuza kugqitywa, i-cutter ayifanele ivaliwe ukuphelisa iimpazamo.

5. Emva kokuba i-abrasive grinding iyancipha, amandla okugaya nawo ayanda, okubangela ukuba iinqununu ze-abrasive ziphule okanye ziwe kwaye ziphinde ziveze umgca obukhali.Olu phawu luba "kukuzilola".Ukuzilola kwenza umsebenzi wokusila ngokuqhelekileyo ngexesha elithile, kodwa emva kwexesha elithile lokusebenza, kufuneka lilungiswe ngesandla ukuze ugweme ukungcangcazela, ingxolo kunye nomonakalo kumgangatho ongaphezulu we-workpiece obangelwa ukwanda kwamandla okugaya.

Ivili lokugaya

Ivili lokugaya sisixhobo sokusika ukugaya.Iqulathe abrasives ezininzi ezincinci kunye ezinzima kunye nezibophelelo, ezenziwe ngezinto ezininzi ezingenanto.Iingqungquthela eziqhekezayo zithwala ngokuthe ngqo umsebenzi wokusika, kufuneka zibe bukhali kwaye zibe nobunzima obuphezulu, ukuchasana nokushisa kunye neqondo elithile lobunzima.Iibrasives ezisetyenziswa ngokuqhelekileyo ziyi-alumina (eyaziwa ngokuba yi-corundum) kunye ne-silicon carbide.

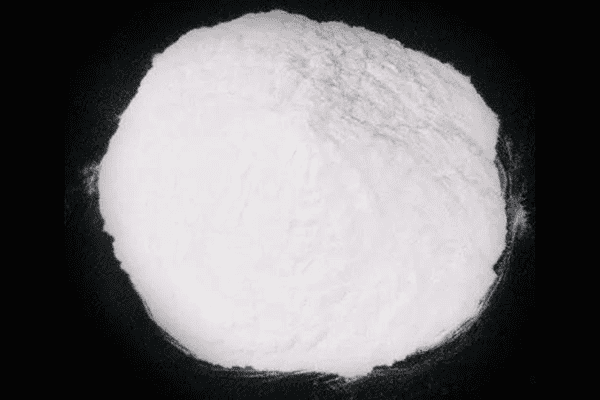

Alumina

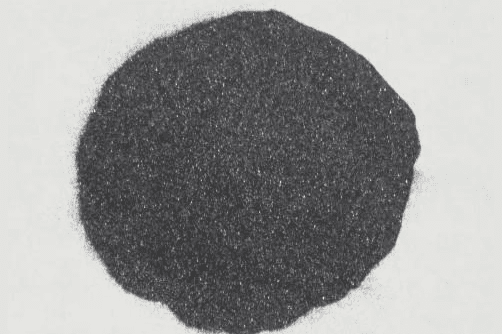

I-Alumina Abrasives inobunzima obuphezulu, ubunzima obuhle kwaye ifanelekile ukugaya intsimbi.I-silicon carbide abrasives inobulukhuni obuphezulu, ibukhali kunye ne-thermal conductivity engcono, kodwa i-brittle kwaye ifanelekile ukucola isinyithi kunye ne-samente carbide.

Ivili lokusila elifanayo elibi, ngenxa yobuninzi bayo obahlukileyo, uburhabaxa bomphezulu kunye nokusebenza kakuhle kwe-workpiece emva kokulungiswa kuyahluka.I-abrasive erhabaxa isetyenziselwa ukusila ngokurhabaxa.I-abrasive incinci, i-coarser i-abrasive, incinci i-particle size.

Izibophelelo zisebenza njengama-abrasives adibanisayo.

I-Ceramic binder isetyenziswa ngokuqhelekileyo, ilandelwa yi-resin binder.Ukukhethwa kwe-binder eyahlukileyo kuchaphazela ukuxhathisa ukubola, amandla, ukumelana nobushushu kunye nokuqina kwevili lokusila.

Ukuqina kwebhondi ye-abrasive, kunzima kakhulu ukuwa kwivili lokusila.Oko kukuthi, ubunzima bevili lokugaya bubhekisela kwinqanaba apho amaqhekeza abrasive ebusweni bevili lokugaya awela phantsi kwesenzo samandla angaphandle.Ukuwa kulula kubizwa ngokuba yinto ethambileyo, kwaye ngokuphambeneyo kuthiwa lukhuni.

Ukuqina kwevili lokusila kunye ne-abrasive zikhonsepthi ezimbini ezahlukeneyo.Umphezulu we-workpiece egayiweyo ithambile, kwaye umda (umda) we-particle abrasive akulula ukuwugqoka, ukwenzela ukuba iinqununu ezinqabileyo zingasetyenziselwa ixesha elide, oko kukuthi, ivili lokugaya elinokubambisana okunamandla ( ivili lokusila ngobulukhuni obuphezulu) linokukhethwa.Ngokuchasene noko, ivili lokugaya elinobunzima obuphantsi lifanelekile ukugaya i-workpiece kunye nobunzima obuphezulu.

Ukuqinisekisa ukhuseleko, amavili okugaya kufuneka ahlolwe ngaphambi kokufakwa, kwaye akufanele kubekho iintanda kunye nezinye iziphene.Ukuze wenze amavili okusila asebenze kakuhle, uvavanyo oluguquguqukayo lwebhalansi kufuneka lwenziwe ngaphambi kokusetyenziswa.

Xa ivili lokugaya lisebenza ixesha elithile, i-voids yomhlaba iya kuvinjelwa yi-debris, i-angle ebukhali ye-abrasive iya kuba yinto enqabileyo, kwaye i-geometric shape yasekuqaleni iya kuphazamiseka.Ngoko ke, kuyimfuneko ukusika ukubuyisela amandla okusika kunye nejometri echanekileyo.Ivili lokugaya kufuneka lilungiswe ngepeni yedayimani.

Ubume kunye neNtshukumo yokuSila yoMashini wokuSila uMphezulu

Kukho iintlobo ezininzi zezinto zokusila, ezifana negrinder yomhlaba, icylindrical grinder, igrinder yangaphakathi, i-universal cylindrical grinder (nayo inokusila imingxuma yangaphakathi), igrinder yegiya, intambo yokusila, isikhokelo sokusila, isisi esingenaziko (ukusila isangqa sangaphandle) kunye nesixhobo sokusila ( isixhobo sokusila).Igrinder yomphezulu kunye nokuhamba kwayo yaziswa apha.

1. Ubume be-grinder yomhlaba (ukuthatha i-M7120A njengomzekelo: isixhobo somatshini wohlobo lwe-M-grinder; i-71-horizontal axis moment type type surface grinder; 20-working table wide 200 mm; A-yokuqala ukuphuculwa okukhulu).

(1) Ivili lokugaya - Faka ivili lokugaya kwaye uqhube ivili ukuze ujikeleze ngesantya esiphezulu.Irekhi yevili lokusila inokuhamba ecaleni komgaqo kaloliwe we-dovetail yesitulo esityibilikayo ngesandla okanye nge-hydraulically kwi-transverse clearance.

(2) Isitulo sesilayidi - faka ivili lokusila kunye nevili lokusila ukuze uhambe unyuka usehla ngomzila kaloliwe wekholamu.

(3) Ikholamu - exhasa isitulo sokutyibilika kunye nesakhelo sevili lokugaya.

(4) I-Workbench - Ukufakwa kwe-workpiece kunye ne-reciprocating linear motion eqhutywa yi-hydraulic system.

(5) Ibhedi - exhasa i-worktable kunye nokufaka ezinye iindawo.

(6) Inkqubo yokupholisa - ukubonelela ngokupholisa (ioli ene-saponified) kwindawo yokusila.

(7) Inkqubo yokuhanjiswa kweHydraulic, ebandakanya:

1) Amacandelo ombane - iimpompo zeoyile, inkqubo yokuhanjiswa kwe-hydraulic yoxinzelelo lweoyile;

2) I-Actuator - i-cylinder, ukuqhuba ukuhamba kwe-worktable kunye namanye amacandelo;

3) Izinto zokulawula - kuzo zonke iintlobo zeevalvu, uxinzelelo lokulawula, isantya, ulwalathiso, njl.

4) Amacandelo ancedisayo, njengetanki yamafutha, i-gauge yoxinzelelo, njl.

Xa kuthelekiswa nokuhanjiswa koomatshini, ukuhanjiswa kwe-hydraulic kunenzuzo yokuhanjiswa okugudileyo, ukukhuselwa komthwalo ogqithisiweyo kunye nokulawulwa kwesantya esingenanyathelo kuluhlu olubanzi.

2. Intshukumo yokusila indiza

(1) Intshukumo ephambili - isantya esijikelezayo esijikelezayo sevili lokusila.

(2) Intshukumo yokutya

1) Isondlo sexesha elide - i-worktable iqhuba intshukumo ehambelanayo yomgca we-workpiece;

2) Ukutya okuthe nkqo - ukuhamba kwevili lokugaya ukuya kubunzulu bomsebenzi;

3) Transverse feed-clearance movement yevili lokusila ecaleni kwe axis yalo.

Ixesha lokuposa: May-23-2019