Natural marble is widely used in modern construction because of its elegance, luxury, wear resistance and corrosion resistance. It is a practical and theoretical problem in engineering quality management to pay attention to the causes of common quality problems of natural marble, its quality control and improvement of construction technology.

Common quality defects and causes of Dali stone installation construction technology

1.1 hollowing of marble wall

On the other hand, marble contains CaCO3 and many kinds of mineral materials and other impurities. The long-term wind, frost, rain, snow and sun will cause its discoloration and fading.

When CaCO3 in marble meets with acids in the air, chemical reaction takes place, forming water-soluble gypsum, which makes its surface dull and rough, leading to pitting cracking and falling off.

1.2 the joint of the plate is not straight, and the texture of the plate surface is not smooth

The main reasons are improper treatment of base or matrix, local concave and convex surface; the finished plates are not strictly selected, with different designs and colors, incorrect specifications, cracks, pollution and damage; no trial assembly number before installation and construction; high layered grouting height; improper construction sequence, etc.

1.3 marble veneer cracking

The main reason is that when the marble board is inlaid on the outer wall or close to the wet space such as kitchen and toilet, the installation is rough, the grouting of the board joint is not strict, the erosive and damp gas infiltrates into the board joint, which makes the metal connector rust and expand, and the marble board cracks under the deformation thrust;

When the color grain dark joint or other hidden defects of marble slab, due to the stress concentration caused by the structural settlement, the weak part of the stone is cracked; when the surface is vertically pasted, the upper and lower spaces are small, the structure is compressed and deformed, and the plate is cracked by the vertical pressure.

1.4 marble veneer damage pollution

The main reasons are the problems of site management, improper operation in the process of plate transportation, storage and ex warehouse, etc.; the residual mortar was not removed immediately during the construction process; the construction site protection work was not done well after the installation.

2 preparation for construction and installation of natural marble materials

2.1 mounting preparation

First, check the actual deviation of the structure according to the design drawings, check the vertical flatness of the base wall, and chisel or repair the parts with large deviation; second, measure the actual height of the column center line, as well as the horizontal line between the upper and lower parts of the column, and determine the specification and size of the veneer block;

For the one side of stair wainscot and complex shape, the side shall be solid first, and if necessary, other materials shall be used for full size detail proofreading. Finally, according to the actual measurement of the specification and size of the wall column, the width of the joint between the decorative panels is calculated, and the plate arrangement is calculated. According to the installation sequence number, the block and node detail drawing is drawn, which is used as the basis for processing and ordering.

2.2 treatment of installation surface and setting out and leveling

First of all, the construction base or base course shall have enough stability and rigidity to make the surface flat but rough. The smooth surface shall be roughened first, with a chiseling depth of 5-15mm and a spacing of > 15mm. The base or base course surface shall have residues such as mortar, dust and oil stains, which shall be brushed with steel wire and then washed with clean water. When the column is inlaid with marble, the center line and horizontal line of the column shall be marked according to the dimension of the building axis as the leveling datum.

2.3 stone inspection and numbering

After the opening of the stone package, strictly select the plates with the same color and specifications without missing edges and corners; then carry out trial assembly according to the design size, cover the square and grind the edges, check the flatness, measure the perpendicularity of the edges and corners, make the size meet the design requirements, control the actual size after inlaying, and ensure the uniform width and height; the color change should be natural, and the color of the same wall or facade should be uniform.

When matching the patterns, try to make the upper, lower, left and right smooth and harmonious, the texture is natural, and the same pattern should be symmetrical, so as to be integrated; when pre matching the numbers, the inlay parts should be strictly selected, and the plates with good texture and color should be used for the main space parts.

3 improvement of natural marble stone construction

The traditional paving technology of natural Dali stone is to pre hang steel mesh lead wire on the base and then pour mortar. This process is tedious, complex and costly. In engineering, it often causes quality problems such as poor adhesion and uneven surface due to improper control.

The improved technology is a new construction technology based on the absorption of foreign advanced technology and the advantages of traditional technology. The construction preparation method of this process is basically the same as that of the traditional process. Other technical points are as follows:

3.1 substrate treatment

Firstly, wet the cleaned substrate with water, pave and plaster 1:1 cement mortar, use coarse sand or medium sand, and brush the back of stone with water to enhance the bonding force;

3.2 plate drilling

Use electric drill to drill holes at 1 / 4 side length from both ends of the plate, with hole depth of 35-40mm and hole diameter of 6mm. When the plate width is ≤ 500mm, the number of holes is 2; when the plate width is > 500mm, the number of holes is 3;

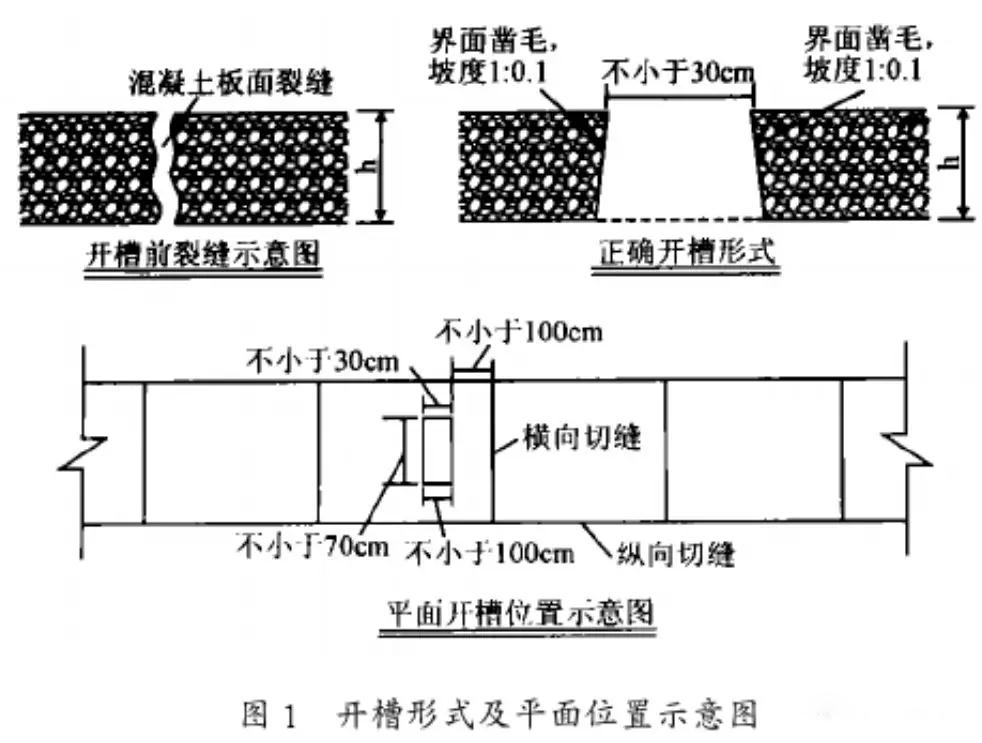

When the plate width is more than 800mm, the number of holes is 4. Then drill a straight hole on both sides of the plate, the hole location is 100mm from the lower end of the plate, the hole diameter is 6mm, the hole depth is 35 ~ 40mm, the length and width of the upper and lower straight holes should be no less than 70cm and 30cm respectively, and the distance from the plate edge should be no less than 100cm, and the slotting form and plane position are shown in Figure 1.

In order to make the new and old concrete combine closely, the slotted interface is chiseled and cleaned, and the fiber concrete and soil can be improved by one grade, that is, C35 super fine sand steel fiber concrete is used.

3.3 through cracks

Most of these cracks are structural stress cracks. Before repairing, it is necessary to determine whether the subgrade and base course are stable. Only when the foundation reaches enough stability can it be repaired.

The form of slotting mostly adopts through slotting or whole board renovation. After repeated tests, the alloy chisel is used to cut the groove at the back with the depth of 6-8mm to install the U-shaped nails.

3.3 matrix drilling

After drilling, the plates shall be temporarily placed in place according to the setting out and block position of the substrate. On the corresponding matrix position with the upper and lower straight holes of the plate, use the impact electric drill to drill the inclined holes with the same number of holes as the plate, the hole inclination is 45 °, the hole diameter is 6mm, and the hole depth is 40-50mm.

3.4 plate installation and fixation

3.4.1 according to the hole distance between the plate and the substrate, use wire pliers to first place the stainless steel ∪ nails with a diameter of 5mm, one end in the straight hole of the plate, and wedge them with hardwood; the other end is placed in the inclined hole of the substrate, with the plate surface vertical, flatness and upper and lower opening of the plate, and correct whether the joint with the adjacent plate is tight, and wedge the stainless steel ∪ nails. Then use big head wood wedge to fasten between the plate and the base, and fasten the U-nail.

3.4.2 correct the plate position accurately, fix it temporarily first, and then grout in layers, without any touch before the mortar is set.

4 quality control of common quality problems in the construction of natural marble

4.1 quality control of hollowing and falling off of marble facing

Carefully handle the top pressing part of outdoor marble facing to ensure that the base course does not penetrate water, especially the transverse joint. In the design, rain cover shall be added on the upper part as far as possible to prevent direct exposure to the rain and sun, and shorten the service life; the stone materials used for the external facing shall be the boards with pure quality, less impurities, less weathering and corrosion resistance.

4.2 quality control of the uneven joint and the unsmooth texture of the board

Make rules for snapping lines on the base course, and divide them into warehouses and grids, pop up the center line and horizontal line on the larger surface, and pop up the marble wall line; check the flatness of the base course before installation, chisel or repair the major deviation, so that the distance between the base course surface and the plate surface is not less than 50 mm, and clean it, water it thoroughly; pick out the plate with missing edges, corners, cracks and local pollution and discoloration in advance, and Conduct nested inspection.

The plates with dimensional deviation shall be polished and corrected; trial assembly shall be carried out according to the snapping line and gauge distance of the wall, the color shall be well adjusted and the pattern shall be adjusted so that the upper and lower left and right textures between the plates are smooth and the color is coordinated; pasting method shall be adopted for small-sized plates, and more firm installation process shall be adopted when the height of large-sized plates or inlays exceeds 1m; after the gypsum slurry is solidified, 1:2.5 cement mortar shall be used for layered grouting, and each grouting shall be carried out The height should not be too high. Otherwise, it is easy to make the board expand and move out, affecting the flatness of the facing

4.3 quality control of marble wall cracking

The gap at the joint of the plate shall not be greater than 0.5 ~ 1mm, so as to ensure tight caulking, full grouting and free of defects such as crack, edge missing and corner dropping, so as to prevent the invasion of corrosive gas and humid air and the corrosion of embedded metal components, which may cause the plate crack;

When inlaying marble veneer on the surface of load-bearing components such as wall column, it shall be carried out after the structure settlement is stable. When installing the marble veneer at the top and bottom, a certain gap will be left to prevent the veneer from being crushed and cracked due to the direct bearing of the structural compression.

4.4 quality control of collision pollution of marble facing

There is a certain gap and dyeing ability between marble particles in Dali, which will permeate and absorb in case of colored liquid, and the marble surface will not be easily removed after being polluted.

Therefore, in the process of transportation and storage, the light marble veneer should not be tied with straw rope and straw shade. In the process of finished product protection, it is not suitable to paste colored packaging to protect the finished product, so as to prevent the product from being polluted by colored liquid after being drenched with water.

During the construction grouting, the joints shall be straight and tight, and the joints shall be filled with hemp silk or filled with hemp knife ash to prevent the leakage of mortar at the joints from causing pollution; the marble is delicate, so it shall be carefully protected during stacking and handling.

When the marble veneer is transported vertically, the front corner or one corner shall not be landed first, so as to prevent the damage of the front corner from affecting the tight fit of the joint. The large-size plates should not be transported horizontally, otherwise, the hidden damage or fracture of the concealed joint and the semi through color joint will be aggravated due to the expansion of the bending moment caused by the self weight of the stone;

After the installation of marble, the protection of the construction site should be done carefully. The inner corners of the column doors, windows and windowsills should be firmly bound with wood plates, and the walls should be covered with plastic film of wood plates. When the stair steps are installed, they should be protected with wood plates at each step

Post time: Nov-06-2019