Ibhastile lendalo lisetyenziswa kakhulu kulwakhiwo lwangoku ngenxa yobuhle balo, ubunewunewu, ukuxhathisa ukunxiba kunye nokumelana nomhlwa.Yingxaki esebenzayo kunye nethiyori ekulawuleni umgangatho wobunjineli ukunikela ingqalelo kwizizathu zeengxaki zomgangatho oqhelekileyo webhastile lendalo, ulawulo lwayo lomgangatho kunye nokuphuculwa kobugcisa bokwakha.

Iziphene ezisemgangathweni eziqhelekileyo kunye nezizathu zeteknoloji yokwakha i-Dali yokufakela ilitye

1.1 ukugrunjwa kodonga lwebhastile

Ngakolunye uhlangothi, i-marble iqulethe i-CaCO3 kunye neentlobo ezininzi zezinto zamaminerali kunye nezinye izinto ezingcolileyo.Umoya wexesha elide, iqabaka, imvula, ikhephu kunye nelanga ziya kubangela ukujika kwemibala kunye nokubuna.

Xa i-CaCO3 kwi-marble idibana ne-acids emoyeni, ukuphendulwa kweekhemikhali kwenzeka, ukwenza i-gypsum e-soluble yamanzi, eyenza umphezulu wayo ube buthuntu kwaye ube rhabaxa, ekhokelela ekuqhekekeni kunye nokuwa.

I-1.2 i-joint ye-plate ayiqondile, kwaye ukuthungwa kwendawo yeplate ayigudi

Izizathu eziphambili kunyango olungafanelekanga lwesiseko okanye i-matrix, i-concave yendawo kunye ne-convex surface;iipleyiti ezigqityiweyo azikhethwanga ngokungqongqo, ngokuyila kunye nemibala eyahlukeneyo, iinkcukacha ezingalunganga, ukuqhekeka, ukungcola kunye nomonakalo;akukho nombolo yendibano yesilingo phambi kofakelo kunye nokwakhiwa;umgangatho ophezulu we-grouting;ukulandelelana kolwakhiwo olungafanelekanga, njl.

1.3 ukuqhekeka kwevene yebhastile

Esona sizathu siphambili kukuba xa ibhodi yebhastile ifakwe eludongeni lwangaphandle okanye kufutshane nendawo emanzi efana nekhitshi kunye nendlu yangasese, ukufakwa kurhabaxa, ukugrunjwa komdibaniso webhodi akungqongqo, igesi ekhukulisekayo kunye nefumileyo ingena ngaphakathi. ibhodi edibeneyo, eyenza i-rust connector yentsimbi kunye nokwandisa, kunye nebhodi le-marble liqhekeka phantsi kwe-deformation thrust;

Xa umbala wenkozo edibeneyo emnyama okanye ezinye iziphene ezifihliweyo ze-marble slab, ngenxa yoxinzelelo loxinzelelo olubangelwa ukuhlaliswa kwesakhiwo, inxalenye ebuthathaka yelitye iyaqhekeka;xa umphezulu uncanyathiselwe ngokuthe nkqo, iindawo eziphezulu nezisezantsi zincinci, isakhiwo sinyanzeliswa kwaye sikhubazekile, kwaye ipleyiti iqhekezwe ngoxinzelelo oluthe nkqo.

1.4 Ungcoliseko lomonakalo owenziwe ngebhastile

Izizathu eziphambili ziingxaki zolawulo lwesayithi, ukusebenza ngokungafanelekanga kwinkqubo yokuthutha ipleyiti, ukugcinwa kunye ne-ex warehouse, njl.;udaka olushiyekileyo aluzange lususwe ngoko nangoko ngexesha lenkqubo yokwakha;umsebenzi wokukhusela indawo yokwakha awuzange wenziwe kakuhle emva kofakelo.

2 ukulungiselela ukwakhiwa kunye nokufakwa kwezinto zendalo zebhastile

2.1 ukulungiselela ukunyuswa

Okokuqala, khangela ukuphambuka kwangempela kwesakhiwo ngokwemizobo yoyilo, jonga i-flatness ethe nkqo yodonga olusisiseko, kunye ne-chisel okanye ulungise iindawo ngokuphambuka okukhulu;okwesibini, ukulinganisa ukuphakama kwangempela komgca weziko lekholomu, kunye nomgca onqamlekileyo phakathi kweendawo eziphezulu kunye nezantsi zekholomu, kwaye unqume ukucaciswa kunye nobukhulu bebhloko ye-veneer;

Kwelinye icala lestair wainscot kunye nemilo entsonkothileyo, icala liya kuba liqina kuqala, kwaye ukuba kukho imfuneko, ezinye imathiriyeli ziya kusetyenziselwa ubungakanani obugcweleyo bovavanyo lovavanyo.Ekugqibeleni, ngokubhekiselele kumlinganiselo wangempela wenkcazo kunye nobukhulu bekholomu yodonga, ububanzi bokudibanisa phakathi kweepaneli zokuhlobisa kubalwa, kwaye ilungiselelo leplate libalwe.Ngokwenombolo yolandelelwano lofakelo, umzobo webhloko kunye ne-node yeenkcukacha izotyiwe, esetyenziswa njengesiseko sokucubungula kunye nokuodola.

2.2 unyango lokufakela umphezulu kunye nokumisela kunye nokulinganisa

Okokuqala, isiseko sokwakha okanye ikhosi yesiseko iya kuba nozinzo olwaneleyo kunye nokuqina ukwenza umphezulu ube mcaba kodwa urhabaxa.Indawo egudileyo kufuneka yenziwe rhabaxa kuqala, ngobunzulu obuyi-5-15mm kunye nesithuba esingaphezulu kwe-15mm.Isiseko okanye umphezulu wesiseko uya kuba neentsalela ezifana nodaka, uthuli kunye namabala e-oyile, aya kuthi ahlanjwe ngocingo lwentsimbi emva koko ahlanjwe ngamanzi acocekileyo.Xa ikholamu ifakwe ngemarble, umgca ophakathi kunye nomgca othe tye wekholamu uya kumakishwa ngokomlinganiselo we-axis yesakhiwo njengedatum yokulinganisa.

2.3 ukuhlolwa kwamatye kunye nokubalwa kwamanani

Emva kokuvulwa kwephakheji yamatye, khetha ngokungqongqo iiplati ezinombala ofanayo kunye neenkcukacha ngaphandle kweengqungquthela ezilahlekileyo kunye neekona;emva koko uqhube indibano yesilingo ngokwesayizi yoyilo, gubungela isikwere kwaye ugaye imiphetho, jonga ukuthambeka, ukulinganisa i-perpendicularity yamaphethelo kunye neekona, wenze ubungakanani buhlangabezane neemfuno zoyilo, lawula ubungakanani bokwenyani emva kokufakwa, kwaye uqinisekise ukuba ububanzi obufanayo kunye nobude;utshintsho lombala kufuneka lube yindalo, kwaye umbala wodonga olufanayo okanye i-facade kufuneka ibe yinto efanayo.

Xa udibanisa iipatheni, zama ukwenza phezulu, ezantsi, ekhohlo nasekunene egudileyo kwaye ehambelanayo, ukuthungwa kungokwemvelo, kunye nomzekelo ofanayo kufuneka ube ne-symmetrical, ukuze udibanise;xa kutshatisa amanani kwangaphambili, iinxalenye ze-inlay kufuneka zikhethwe ngokungqongqo, kwaye iipleyiti ezinobumba obuhle kunye nombala kufuneka zisetyenziswe kwiindawo eziphambili zendawo.

I-3 yokuphucula ukwakhiwa kwamatye e-marble yendalo

Itekhnoloji yemveli yokugalela ilitye lendalo leDali kukuxhoma ngaphambili ucingo lwentsimbi olunemesh kwisiseko emva koko ugalele udaka.Le nkqubo iyadika, intsonkothile kwaye iyabiza.Kwinjineli, ihlala ibangela iingxaki ezisemgangathweni ezinje ngokubambelela kakubi kunye nomphezulu ongalinganiyo ngenxa yolawulo olungafanelekanga.

Ubuchwephesha obuphuculweyo bubuchwephesha bokwakha obutsha obusekwe ekufunxeni kobuchwephesha obuhambele phambili bamazwe angaphandle kunye neenzuzo zobugcisa bemveli.Indlela yokulungiselela ukwakhiwa kwale nkqubo ngokusisiseko iyafana naleyo yenkqubo yemveli.Ezinye iindawo zobugcisa zezi zilandelayo:

3.1 unyango lwe-substrate

Okokuqala, manzisa i-substrate ecociweyo ngamanzi, igayiva kunye nodaka lwesamente ye-1: 1, sebenzisa isanti erhabaxa okanye isanti ephakathi, kwaye uhlambe umva welitye ngamanzi ukuqinisa amandla okudibanisa;

3.2 ukomba ipleyiti

Sebenzisa i-electric drill ukugrumba imingxuma kwi-1/4 yecala ubude ukusuka kwiziphelo zombini zepleyiti, ubunzulu bomngxuma obuyi-35-40mm kunye ne-6mm yomngxuma.Xa ububanzi beplate ≤ 500mm, inani lemingxuma yi-2;xa ububanzi bepleyiti bu> 500mm, inani lemingxuma yi-3;

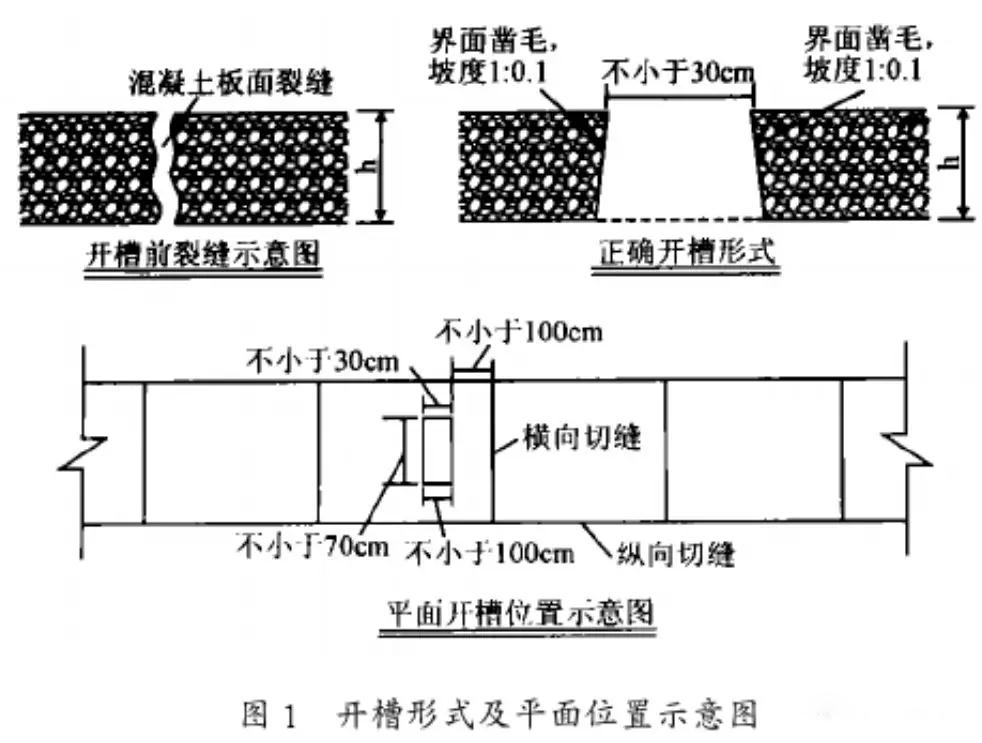

Xa ububanzi beplate bungaphezulu kwe-800mm, inani lemingxuma yi-4. Emva koko ubhobhoze umngxuma othe tye kumacala omabini epleyiti, indawo yomngxuma i-100mm ukusuka ekupheleni kweplate, ububanzi bomngxuma yi-6mm, ubunzulu bomgodi. yi-35 ~ 40mm, ubude kunye nobubanzi bemingxuma ephezulu kunye nesezantsi ethe tye kufuneka ingabi ngaphantsi kwe-70cm kunye ne-30cm ngokulandelelana, kwaye umgama ukusuka kumda weplate kufuneka ungabi ngaphantsi kwe-100cm, kwaye ifom yokubeka kunye nendawo yendiza iboniswe Umfanekiso woku-1.

Ukuze wenze ikhonkrithi entsha nendala idibanise ngokusondeleyo, i-interface edibeneyo ifakwe kwaye icocwe, kwaye ikhonkrithi yefiber kunye nomhlaba unokuphuculwa ngebakala elinye, oko kukuthi, i-C35 yesanti ecolekileyo ye-fiber yentsimbi yekhonkrithi isetyenziswa.

3.3 ngokusebenzisa iintanda

Uninzi lwezi iintanda ziintanda zoxinzelelo lwesakhiwo.Ngaphambi kokulungiswa, kuyimfuneko ukugqiba ukuba i-subgrade kunye nekhosi yesiseko zizinzile.Kuphela xa isiseko sifikelela kuzinzo olwaneleyo sinokulungiswa.

Indlela yokubeka ubukhulu becala ithathwa ngokubeka ibhodi okanye ukulungiswa kwebhodi yonke.Emva kovavanyo oluphindaphindiweyo, i-alloy chisel isetyenziselwa ukusika i-groove ngasemva kunye nobunzulu be-6-8mm ukufaka izikhonkwane ze-U.

3.3 ukugrumba imatrix

Emva kokubhoboza, iiplate ziya kufakwa okwethutyana ngokuhambelana nokumiswa kunye nebhloko yendawo ye-substrate.Kwindawo ye-matrix ehambelanayo kunye nemingxunya ephezulu kunye nesezantsi ethe tye yepleyiti, sebenzisa i-drill yombane yempembelelo ukubhobhoza imingxuma ethambekele enenani elifanayo lemingxuma njengepleyiti, ukuthambekela komngxuma yi-45 °, ububanzi bomngxuma yi-6mm, kwaye umngxuma ubunzulu 40-50mm.

3.4 ukufakwa kwepleyiti kunye nokulungiswa

3.4.1 ngokomgama womngxuma phakathi kwepleyiti kunye ne-substrate, sebenzisa iipliers zocingo ukubeka kuqala intsimbi engenasici ∪ izikhonkwane ezinobubanzi obuyi-5mm, enye isiphelo kumngxunya othe ngqo wepleyiti, kwaye uzidibanise ngomthi onzima;Esinye isiphelo sibekwe kumngxunya ochongiweyo we-substrate, kunye neplate yomhlaba ngokuthe nkqo, ukuvuleka kunye nokuvuleka okuphezulu kunye nasezantsi kwepleyiti, kwaye ulungise ukuba i-joint kunye ne-plate esecaleni iqinile, kwaye i-wedge insimbi engenasici ∪ izikhonkwane.Emva koko sebenzisa i-wedge enkulu yomthi ukuqhoboshela phakathi kwepleyiti kunye nesiseko, kwaye ubophe isikhonkwane se-U.

3.4.2 lungisa indawo yepleyiti ngokuchanekileyo, yilungise okwethutyana kuqala, kwaye emva koko ugruthe ngokwemaleko, ngaphandle kokuthinta phambi kokuba udaka lusetwe.

Ukulawulwa kwekhwalithi ye-4 yeengxaki eziqhelekileyo zomgangatho ekwakhiweni kwebhastile yendalo

4.1 ulawulo lomgangatho wokugrunjwa kunye nokuwa kwelitye lebhastile elijongene nayo

Phatha ngononophelo indawo ecinezelayo ephezulu yelitye lebhastile elingaphandle elijonge ukuqinisekisa ukuba isiseko asingeni emanzini, ngakumbi indawo enqamlezileyo.Kuyilo, isigqubuthelo semvula siya kongezwa kwindawo ephezulu ngokusemandleni ukukhusela ukutshatyalaliswa ngokuthe ngqo kwimvula kunye nelanga, kunye nokunciphisa ubomi benkonzo;izinto zamatye ezisetyenziselwa ukujongana kwangaphandle ziya kuba ziibhodi ezinomgangatho ococekileyo, ukungcola okuncinci, ukungabikho kwemozulu kunye nokuchasana nokugqwala.

4.2 Ukulawulwa komgangatho wejoyinti elingalinganiyo kunye nokuthungwa okungaguqukiyo kwebhodi

Yenza imithetho yokuqhawula imigca kwikhosi yesiseko, kwaye ulwahlule kwiindawo zokugcina iimpahla kunye neegridi, uphume umgca ophakathi kunye nomgca othe tye kwindawo enkulu, kwaye uvele umgca wodonga lwemarble;jonga i-flatness yekhosi yesiseko phambi kofakelo, i-chisel okanye ulungise ukutenxa okukhulu, ukwenzela ukuba umgama phakathi kwendawo yekhosi yesiseko kunye nomgangatho weplate ungekho ngaphantsi kwe-50 mm, kwaye uyicoce, uyinkcenkceshele ngokucokisekileyo;khetha ipleyiti enencam ezilahlekileyo, iikona, iintanda kunye nongcoliseko lwendawo kunye nokutshintsha kombala kwangaphambili, kwaye Uqhube uhlolo olubekwe kwindlwane.

Amacwecwe ane-dimensional deviation aya kugudiswa kwaye alungiswe;indibano yesilingo iya kwenziwa ngokomgca wokuqhawula kunye nomgama wegeyiji eludongeni, umbala uya kulungelelaniswa kakuhle kwaye ipateni iya kulungelelaniswa ukuze ukwakheka okungaphezulu kunye nasezantsi ekhohlo nasekunene phakathi kwamacwecwe agudileyo kwaye umbala ulungelelaniswe. ;indlela yokuncamathisela iya kwamkelwa kwiipleyiti ezinobungakanani obuncinci, kwaye inkqubo yofakelo oluqinileyo iya kwamkelwa xa ukuphakama kwamacwecwe amakhulu okanye ama-inlay adlula i-1m;emva kokuba i-gypsum slurry iqinisiwe, i-1: 2.5 i-cement mortar iya kusetyenziselwa i-layer grouting, kwaye i-grouting nganye iya kuqhutywa Ukuphakama akufanele kube phezulu kakhulu.Ngaphandle koko, kulula ukwenza ibhodi ukuba yandise kwaye ihambe, ichaphazela i-flatness ejongene nayo

4.3 Ukulawulwa komgangatho wokuqhekeka kodonga lwebhastile

Umsantsa kwindawo ekudityaniswa kuyo ipleyiti awuyi kuba mkhulu kune-0.5 ~ 1mm, ukuze kuqinisekiswe i-caulking eqinile, i-grouting epheleleyo kwaye ayinaziphene ezifana nokuqhekeka, ukungabikho komphetho kunye nokuwa kwekona, ukuze kuthintelwe ukuhlaselwa kwegesi enobungozi kunye umoya omanzi kunye nokugqwala kwezinto zetsimbi ezifakwe ngaphakathi, ezinokubangela ukuba ipleyiti iqhekeke;

Xa kufakwe i-marble veneer phezu kwezinto ezithwala umthwalo ezifana nekholamu yodonga, iya kuqhutywa emva kokuba ukulungiswa kwesakhiwo kuzinzile.Xa ufaka i-marble veneer phezulu nasezantsi, i-gap ethile iya kushiywa ukukhusela i-veneer ukuba ingacunyuki kwaye iqhekezwe ngenxa yokuthwala ngokuthe ngqo ukunyanzeliswa kwesakhiwo.

4.4 Ukulawulwa komgangatho wokuntlitheka kongcoliseko lwebhastile elijongene nalo

Kukho i-gap ethile kunye nokukwazi ukudaya phakathi kwamaqhekeza e-marble e-Dali, eya kungena kwaye ifunxe xa kukho ulwelo olunemibala, kwaye umphezulu we-marble awuyi kususwa ngokulula emva kokungcoliswa.

Ngoko ke, kwinkqubo yokuthutha kunye nokugcinwa, i-marble veneer ekhanyayo akufanele iboshwe ngentambo ye-straw kunye nomthunzi we-straw.Kwinkqubo yokukhusela imveliso egqityiweyo, akufanelekanga ukuncamathisela ukupakishwa kombala ukukhusela umkhiqizo ogqityiweyo, ukwenzela ukuba uthintele imveliso ekungcolisweni kolwelo olunemibala emva kokugalelwa ngamanzi.

Ngexesha le-grouting yolwakhiwo, amakhonkco aya kuthi tye kwaye aqine, kwaye amajoyina aya kuzaliswa ngesilika ye-hemp okanye azaliswe ngothuthu lwe-hemp knife ukuthintela ukuvuza kodaka kumalungu ekubangeleni ungcoliseko;Ibhastile lithambile, ngoko ke liya kukhuselwa ngononophelo ngexesha lokupakishwa kunye nokuphathwa.

Xa intsimbi yebhastile ithuthwa ngokuthe nkqo, ikona yangaphambili okanye ikona enye ayizukubekwa kuqala, ukuze kuthintelwe umonakalo wekona yangaphambili ekuchaphazeleni ukulingana okuqinileyo kwendawo edibeneyo.Iipleyiti ezinobungakanani obukhulu akufanele zihanjiswe ngokuthe tye, ngaphandle koko, umonakalo ofihliweyo okanye ukwaphuka komxube ofihliweyo kunye ne-semi ngokusebenzisa umbala odibeneyo uya kuba nzima ngenxa yokwandiswa komzuzu wokugoba obangelwa ubunzima belitye;

Emva kokufakwa kwemarble, ukukhuselwa kwendawo yokwakha kufuneka kwenziwe ngononophelo.Iikona zangaphakathi zeengcango zekholomu, iifestile kunye neefestile kufuneka ziboshwe ngokuqinileyo ngamaplanga okhuni, kwaye iindonga kufuneka zifakwe ifilimu yeplastiki yeeplate zokhuni.Xa izitepsi zifakwe, kufuneka zikhuselwe ngeeplate zokhuni kwinqanaba ngalinye

Ixesha lokuposa: Nov-06-2019