Ana amfani da marmara na dabi'a sosai a ginin zamani saboda kyawun sa, alatu, juriya da juriya na lalata.Yana da matsala mai amfani da ka'ida a cikin sarrafa ingancin injiniya don kula da abubuwan da ke haifar da matsalolin ingancin gama gari na marmara na halitta, sarrafa ingancin sa da haɓaka fasahar gini.

Lalacewar inganci na gama gari da kuma abubuwan da ke haifar da fasahar ginin dutsen Dali

1.1 hollowing na marmara bango

A gefe guda kuma, marmara ya ƙunshi CaCO3 da nau'ikan kayan ma'adinai da sauran ƙazanta.Iska na dogon lokaci, sanyi, ruwan sama, dusar ƙanƙara da rana za su haifar da canza launinsa da dushewa.

Lokacin da CaCO3 a cikin marmara ya sadu da acid a cikin iska, sinadari yana faruwa, yana samar da gypsum mai narkewa da ruwa, wanda ya sa samansa ya zama mara nauyi kuma yana da ƙarfi, yana haifar da fashewa da faɗuwa.

1.2 haɗin gwiwa na farantin ba daidai ba ne, kuma nau'in nau'in farantin ba shi da santsi

Babban dalilai shine rashin kulawa da tushe ko matrix, maƙarƙashiya na gida da farfajiya;faranti da aka gama ba a zaɓa sosai ba, tare da zane-zane da launuka daban-daban, ƙayyadaddun ƙayyadaddun da ba daidai ba, fasa, gurɓatawa da lalacewa;babu lambar taro na gwaji kafin shigarwa da ginawa;high Layered grouting tsawo;tsarin ginin da bai dace ba, da sauransu.

1.3 marmara veneer fatattaka

Babban dalili shi ne, a lokacin da katakon marmara aka sanya shi a bangon waje ko kuma kusa da wurin da ake jika kamar dafa abinci da bayan gida, shigarwar yana da ƙarfi, grouting na haɗin gwiwar allon ba shi da tsauri, iskar gas mai ƙyalƙyali da ɗanɗano yana shiga cikin gidan. haɗin ginin allo, wanda ke sa mai haɗin ƙarfe ya yi tsatsa da faɗaɗawa, kuma katakon marmara yana fashe a ƙarƙashin turawar nakasa;

Lokacin da launin hatsi mai duhu haɗin gwiwa ko wasu ɓoyayyun lahani na katako na marmara, saboda damuwa da damuwa da tsarin tsarin ya haifar, raunin ɓangaren dutse ya fashe;lokacin da aka liƙa saman a tsaye, wurare na sama da ƙananan ƙananan ƙananan, tsarin yana matsawa kuma ya lalace, kuma farantin yana fashe ta hanyar matsa lamba.

1.4 marmara veneer lalacewa gurbatawa

Babban dalilan su ne matsalolin sarrafa wuraren, rashin aiki mara kyau a cikin tsarin jigilar faranti, ajiyar ajiya da tsohon sito, da dai sauransu;Ba a cire ragowar turmi nan da nan yayin aikin ginin ba;aikin kariya na wurin ginin bai yi kyau ba bayan shigarwa.

2 shirye-shiryen ginawa da shigarwa na kayan marmara na halitta

2.1 shiri na hawa

Da farko, bincika ainihin ɓacin rai na tsarin bisa ga zane-zanen ƙira, duba madaidaicin bangon bangon tushe, da chisel ko gyara sassan tare da babban karkata;na biyu, auna ainihin tsayin layin tsakiya na ginshiƙi, da kuma layin kwance tsakanin manyan sassa na sama da ƙananan ginshiƙan, kuma ƙayyade ƙayyadaddun ƙayyadaddun da girman shingen veneer;

Don gefe ɗaya na bene na bene da siffa mai rikitarwa, gefen zai kasance da ƙarfi da farko, kuma idan ya cancanta, za a yi amfani da wasu kayan don cikakken girman karatun dalla-dalla.A ƙarshe, bisa ga ainihin ma'auni na ƙayyadaddun ƙayyadaddun ƙayyadaddun da girman bangon bango, an ƙididdige nisa na haɗin gwiwa tsakanin sassan kayan ado, kuma an ƙididdige tsarin farantin.Dangane da lambar jeri na shigarwa, an zana toshe da zane dalla-dalla, wanda ake amfani da shi azaman tushen sarrafawa da oda.

2.2 jiyya na shigarwa surface da kafa da kuma matakin

Da farko dai, ginin tushe ko hanya mai tushe dole ne ya sami isasshen kwanciyar hankali da tsauri don sanya saman ya faɗi amma mara ƙarfi.Za a fara fara yin ƙunci mai santsi, tare da zurfin chiseling na 5-15mm da tazarar> 15mm.Filin tushe ko tushe zai kasance yana da ragowar kamar turmi, ƙura da tabon mai, waɗanda za a goge su da waya ta ƙarfe sannan a wanke da ruwa mai tsabta.Lokacin da aka shigar da ginshiƙi tare da marmara, layin tsakiya da layin kwance na ginshiƙi za a yi alama daidai da girman ginin ginin azaman datum mai daidaitawa.

2.3 dutse dubawa da lambobi

Bayan buɗe kunshin dutse, zaɓin faranti da yawa tare da launi iri ɗaya da ƙayyadaddun bayanai ba tare da ɓata gefuna da sasanninta ba;sa'an nan gudanar da gwaji taro bisa ga zane size, rufe square da nika gefuna, duba flatness, auna perpendicularity na gefuna da sasanninta, sa girman saduwa da zane da bukatun, sarrafa ainihin girman bayan inlaying, da kuma tabbatar da fadin uniform da tsayi;canjin launi ya kamata ya zama na halitta, kuma launi na bango ɗaya ko facade ya zama daidai.

Lokacin da ya dace da alamu, yi ƙoƙarin yin babba, ƙananan, hagu da dama da santsi da jituwa, rubutun abu ne na halitta, kuma irin wannan tsari ya kamata ya kasance daidai, don haɗawa;lokacin da ake daidaita lambobi, ya kamata a zaɓi sassan inlay sosai, kuma a yi amfani da faranti masu kyau da launi don manyan sassan sararin samaniya.

3 inganta na halitta marmara dutse yi

Fasahar shimfidar shimfidar wuri ta gargajiya ta dutsen Dali ita ce kafin a rataya wayan gubar karfen karfe a gindi sannan a zuba turmi.Wannan tsari yana da wahala, mai rikitarwa da tsada.A cikin aikin injiniya, sau da yawa yana haifar da matsalolin inganci kamar ƙarancin mannewa da ƙasa mara daidaituwa saboda kulawa mara kyau.

Ingantacciyar fasaha sabuwar fasaha ce ta gini bisa la'akari da fasahohin ci gaba na kasashen waje da fa'idar fasahar gargajiya.Hanyar shirye-shiryen ginin wannan tsari daidai yake da na tsarin gargajiya.Sauran abubuwan fasaha sune kamar haka:

3.1 substrate jiyya

Da fari dai, jika kayan da aka tsabtace da ruwa, pave da plaster 1: 1 turmi siminti, yi amfani da yashi mai laushi ko matsakaiciyar yashi, kuma goge bayan dutse da ruwa don haɓaka ƙarfin haɗin gwiwa;

3.2 farantin hakowa

Yi amfani da rawar sojan lantarki don haƙa ramuka a tsayin gefen 1/4 daga ƙarshen farantin, tare da zurfin rami na 35-40mm da diamita na rami na 6mm.Lokacin da nisa farantin shine ≤ 500mm, adadin ramuka shine 2;lokacin da fadin farantin ya kasance> 500mm, adadin ramukan shine 3;

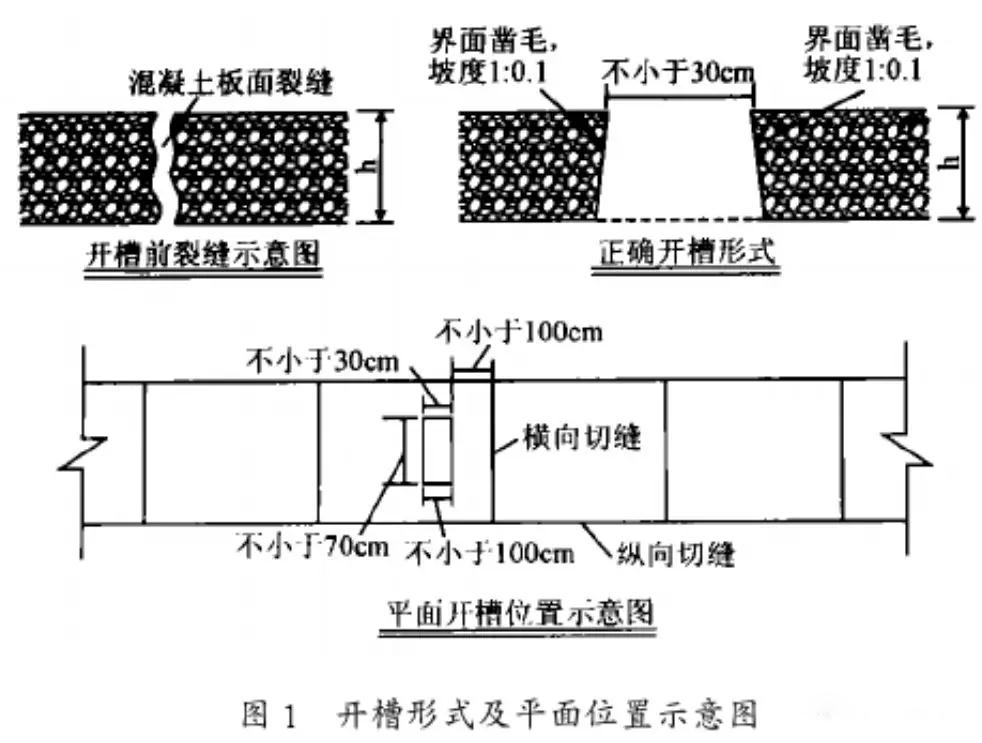

Lokacin da fadin farantin ya fi 800mm, adadin ramukan shine 4. Sa'an nan kuma yi rami madaidaiciya a bangarorin biyu na farantin, wurin rami yana da 100mm daga ƙananan ƙarshen farantin, diamita ramin shine 6mm, zurfin rami. shine 35 ~ 40mm, tsayi da nisa na babba da ƙananan ramukan madaidaiciya yakamata ya zama ƙasa da 70cm da 30cm bi da bi, kuma nisa daga gefen farantin ya kamata ba ƙasa da 100cm ba, kuma ana nuna nau'in slotting da matsayi na jirgin sama a ciki. Hoto 1.

Domin a sa sabon da tsohon siminti su haɗu sosai, ana cire maɓalli mai ramin rami da tsaftacewa, kuma ana iya inganta simintin fiber da ƙasa da maki ɗaya, wato C35 super fine sand karfe fiber kankare.

3.3 ta hanyar fasa

Yawancin waɗannan fasahohi sune tsagewar damuwa na tsarin.Kafin gyarawa, ya zama dole don sanin ko tsarin ƙasa da tushe sun tabbata.Sai kawai lokacin da tushe ya kai isasshen kwanciyar hankali za a iya gyara shi.

Siffar slotting galibi tana ɗauka ta hanyar slotting ko duka gyaran allo.Bayan gwaje-gwajen da aka maimaita, ana amfani da gunkin alloy don yanke tsagi a baya tare da zurfin 6-8mm don shigar da kusoshi masu siffar U.

3.3 matrix hakowa

Bayan hakowa, za a sanya faranti na ɗan lokaci a wuri bisa ga saiti da kuma toshe matsayi na substrate.A daidai matrix matsayi tare da babba da ƙananan madaidaicin ramukan farantin, yi amfani da tasirin wutar lantarki mai tasiri don rawar jiki da ramukan da ke da ramuka iri ɗaya kamar farantin, ramin ramin shine 45 °, ramin rami shine 6mm, kuma zurfin rami shine 40-50mm.

3.4 farantin shigarwa da gyarawa

3.4.1 bisa ga nisa mai nisa tsakanin farantin da substrate, yi amfani da pliers waya don fara sanya bakin karfe ∪ ƙusoshi tare da diamita na 5mm, daya ƙarshen a cikin madaidaiciyar rami na farantin, da kuma sanya su da katako;sauran ƙarshen an sanya shi a cikin ramin karkata na substrate, tare da farantin saman a tsaye, shimfidawa da buɗewa na sama da ƙananan farantin, kuma gyara ko haɗin gwiwa tare da farantin kusa da shi yana da ƙarfi, kuma ya yanke bakin karfe ∪ kusoshi.Sa'an nan kuma yi amfani da babban gunkin itacen kai don ɗaure tsakanin farantin da tushe, kuma a ɗaure U-ƙusa.

3.4.2 gyara wurin farantin daidai, gyara shi na ɗan lokaci da farko, sa'an nan kuma grout a cikin yadudduka, ba tare da taɓawa ba kafin a saita turmi.

4 ingancin kula da na kowa ingancin matsaloli a cikin gina na halitta marmara

4.1 ingancin iko na hollowing da fadowa daga marmara fuskantar

A hankali rike babban ɓangaren matsi na marmara na waje yana fuskantar don tabbatar da cewa hanyar tushe ba ta ratsa ruwa ba, musamman madaidaicin haɗin gwiwa.A cikin zane, za a ƙara murfin ruwan sama a kan ɓangaren sama kamar yadda zai yiwu don hana kai tsaye ga ruwan sama da rana, da kuma rage tsawon rayuwar sabis;kayan dutse da aka yi amfani da su don fuskantar waje za su kasance alluna tare da inganci mai tsabta, ƙarancin ƙazanta, ƙarancin yanayi da juriya na lalata.

4.2 ingantacciyar kulawar haɗin gwiwa mara daidaituwa da ƙarancin rubutu na allo

Yi dokoki don ɗaukar layukan kan hanya mai tushe, kuma raba su cikin ɗakunan ajiya da grids, tashi layin tsakiya da layin kwance akan babban saman, da buɗa layin bangon marmara;duba lebur na kwas ɗin tushe kafin shigarwa, chisel ko gyara babban ɓarna, ta yadda nisa tsakanin filin kwas ɗin tushe da saman farantin bai wuce 50 mm ba, kuma tsaftace shi, shayar da shi sosai;Zabi farantin da bacewar gefuna, sasanninta, tsagewa da gurɓatawar gida da canza launi a gaba, kuma gudanar da binciken gida.

Za a goge faranti tare da karkatar da girma kuma a gyara su;Za a gudanar da taron gwaji bisa ga layin tsinkewa da nisan ma'auni na bangon, launi za a daidaita shi da kyau kuma za a daidaita tsarin don girman da ƙananan hagu da dama a tsakanin faranti suna da santsi kuma launi yana daidaitawa. ;za a yi amfani da hanyar liƙa don ƙananan faranti, kuma za a ɗauki ƙarin tsarin shigarwa lokacin da tsayin manyan faranti ko inlays ya wuce 1m;Bayan an ƙarfafa gypsum slurry, 1: 2.5 za a yi amfani da turmi na ciminti don yin amfani da kayan aiki mai laushi, kuma kowane grouting za a gudanar da tsayin daka ba zai yi girma ba.In ba haka ba, yana da sauƙi don sa allon ya faɗaɗa kuma ya fita, yana shafar shimfidar fuska

4.3 ingancin kula da bangon marmara

Rata a haɗin gwiwa na farantin ba zai zama mafi girma fiye da 0.5 ~ 1mm, don tabbatar da m caulking, cikakken grouting da free of lahani kamar crack, gefen ɓacewa da faduwa kusurwa, don hana mamayewa na lalata gas da kuma iska mai ɗanɗano da lalata kayan ƙarfe da aka haɗa, wanda zai iya haifar da tsagewar farantin;

Lokacin shigar da veneer na marmara a saman abubuwan da ke ɗauke da kaya kamar ginshiƙin bango, za a aiwatar da shi bayan daidaitawar tsarin.Lokacin shigar da murfin marmara a sama da ƙasa, za a bar wani tazari don hana abin da aka murƙushe shi da fashe saboda kai tsaye na matsawa tsarin.

4.4 ingancin kula da karo gurbacewar marmara

Akwai wata tazara da iya rini tsakanin barbashi na marmara a cikin Dali, wanda zai ratsa ya sha ruwa idan akwai ruwa kala-kala, kuma ba za a iya cire saman marmara cikin sauki ba bayan an gurbata shi.

Sabili da haka, a cikin tsarin sufuri da adanawa, kada a ɗaure katakon marmara mai haske da igiya bambaro da inuwar bambaro.A cikin aiwatar da kariyar ƙãre samfurin, bai dace da manna marufi masu launi don kare samfurin da aka gama ba, don hana samfurin daga gurbatawa da ruwa mai launi bayan an shafe shi da ruwa.

A lokacin aikin grouting, gidajen abinci za su kasance madaidaiciya kuma a matse su, kuma a cika mahaɗin da siliki na hemp ko kuma a cika su da tokar wuƙa na hemp don hana zubar da turmi a gidajen abinci daga haifar da gurɓata yanayi;marmara yana da laushi, don haka za a kiyaye shi a hankali yayin tarawa da sarrafawa.

Lokacin da aka yi jigilar dutsen marmara a tsaye, kusurwar gaba ko kusurwa ɗaya ba za a fara saukowa da farko ba, don hana lalacewar kusurwar gaba daga tasiri mai mahimmanci na haɗin gwiwa.Ba za a yi jigilar faranti masu girma a kwance ba, in ba haka ba, ɓoyayyun lalacewa ko ɓarna na haɗin gwiwa da aka ɓoye da kuma rabin ta hanyar haɗin launi za a kara tsanantawa saboda fadada lokacin lanƙwasawa wanda ya haifar da nauyin kai na dutse;

Bayan shigar da marmara, ya kamata a yi la'akari da kariya daga wurin ginin.Ya kamata a ɗaure sasanninta na ciki na ƙofofin ginshiƙan, tagogi da windowssills da kyau tare da faranti na itace, kuma ya kamata a rufe bango da fim ɗin filastik na faranti na katako.Lokacin da aka shigar da matakan matakan, ya kamata a kiyaye su da faranti na itace a kowane mataki

Lokacin aikawa: Nuwamba-06-2019