Stone patchwork is a kind of exquisite natural stone painting that people use stone instead of pigments through artistic conception. It is mainly made use of the natural unique color, texture and material of natural stone, together with ingenious artistic conception and design.

Stone patchwork, in fact, can be seen as a development and extension of mosaic technology, is a new stone product derived from the combination of mosaic technology and new processing technology. Like the early stone mosaic, mosaic is mosaic of stone products, which can be regarded as enlarged version of the stone mosaic. In the later stage, due to the application of water knife technology and the improvement of processing accuracy, the mosaic mosaic technology has been brought into full play and formed its own unique style. But in foreign countries, stone mosaic still belongs to the category of stone mosaic.

Because of the rich and changeable layout effect of natural marble, and the fine texture and moderate hardness of marble, it is very suitable for the processing of mosaic, so most of the mosaic of stone is made of marble, so commonly referred to as stone mosaic, sometimes also refers to marble mosaic. And now the newly developed sandstone and slate patchwork is also very characteristic, but the application is relatively small.

With the development of stone processing technology and design, as well as the complexity of pattern and design of stone mosaic, stone water knife cutting equipment is widely used in the processing of stone mosaic, and for complex mosaic design, water knife has become an indispensable tool, so stone mosaic is also called water knife mosaic.

I. Processing Principle of Stone Matching

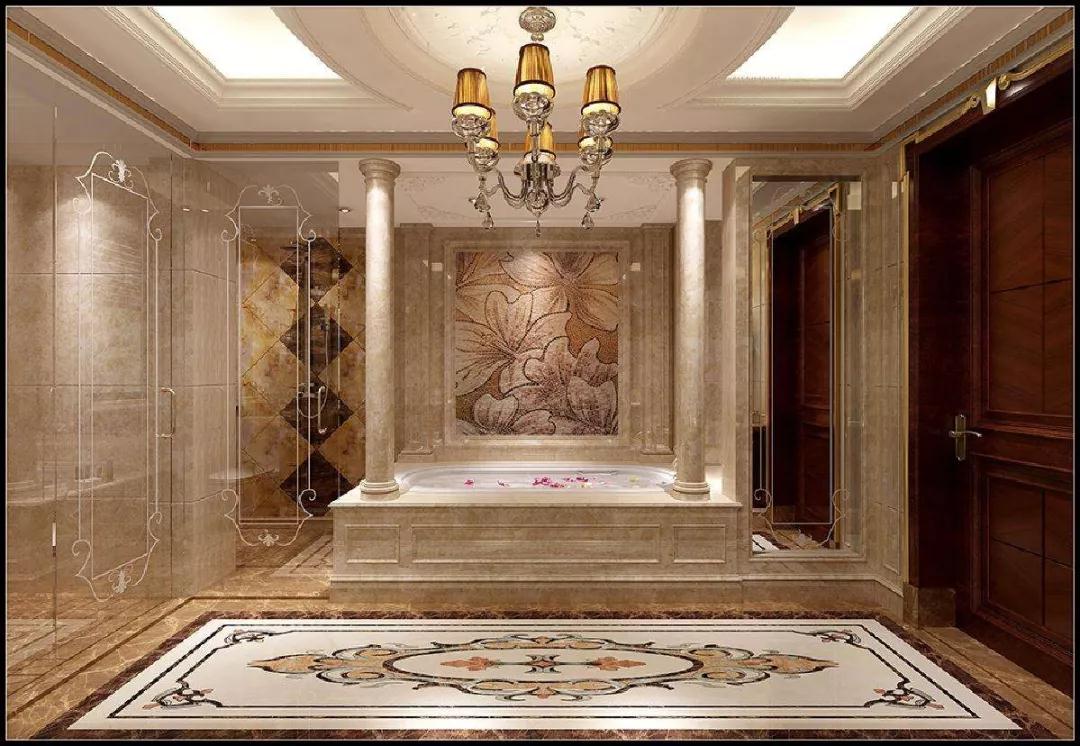

Stone mosaic is widely used in modern architecture for decoration of floor, wall and mesa. With its natural beauty of stone (color, texture, material) and people’s artistic conception, “mosaic” gives a beautiful pattern.Its processing principle is: using computer aided drawing software (CAD) and computer numerical control programming software (CNC) to convert the designed pattern into NC program through CAD, then transmit NC program to NC water cutting machine, and cut various materials into different pattern components with NC water cutting machine. Later, each stone pattern component is joined and bonded into a whole manually to complete the process of water knife splicing.

II. Design and Processing of Stone Mosaic

(1) Design of stone patchwork

In order to design stone works of art which are beautiful, practical, artistic and popular with consumers, we must go deep into life, observe and understand people’s love and needs, and capture creative inspiration from life. Painting composition should originate from life, be higher than life, and be innovative. As long as you observe more and use your brain, your potential and function can be fully developed, and good works of art will be displayed on the drawing paper.

(2) Material selection of stone mosaic

Material for mosaic is very abundant, and leftovers can be used everywhere. As long as we carefully select high-quality materials with brilliant colors and consistent stone color, and process them artistically, we can produce excellent and colorful art treasures.

Stone patchwork, small-scale use of a variety of stone corner waste, large-scale plate. Through design, selection, cutting, gluing, grinding, polishing and other processes, we can create ornamental and artistic stone crafts. It is an art pattern ornament that integrates stone processing art, decoration design art and aesthetic art. Decorated on the surface of the floor, walls, tables and furniture, giving people a refreshing and pleasant, natural and generous feeling. The big puzzle is mounted on the ground of the auditorium, ballroom and square. Its magnificence and grandeur call you to a brilliant tomorrow.

Material selection: In principle, the material selection of stone mosaic depends on the material requirement put forward by the customer to the salesman at the time of ordering. In the absence of any material selection requirements from customers, the material selection shall be in accordance with the national standards for material selection in the stone industry of the country.

Color: The whole stone patchwork must be the same color, but for some materials (Spanish beige, old beige, coral red and other marble) which have color difference on the same board, the principle of gradual color transition is adopted to select materials, with the principle of not affecting the aesthetic decorative effect of patchwork as the principle. When it is impossible to achieve good decorative effect and meet customer’s processing requirements, after obtaining customer’s consent, material processing can be selected.

Patterns: In the process of stone mosaic, the direction of patterning should depend on the specific situation. There is no standard to refer to. As far as the circular stone patchwork is concerned, the pattern can go around the circumference direction or along the radius direction. Whether along the circumference direction or along the radius direction. The consistency of the lines should be ensured. As far as the square stone pattern is concerned, the pattern can radiate along the length direction, along the width direction, or at the same time along the direction of the long main attack width to the four sides. As for how to do, it depends on the processing of the stone pattern to achieve better decorative effect.

(3) Making of stone patchwork

There are five steps in the production of stone mosaic.

1. Drawing die. According to the design requirements, the mosaic pattern is depicted on the drawing paper and copied on three splints with duplicate paper, indicating the colour of the stones used for each pattern. According to the direction of the connection between the patterns, write the number to prevent disorder. Then with a sharp knife, along the lines of the pattern piece by piece, cut out the graphics mold. The cut-in line should be vertical, not oblique, and the arc angle should not be displaced.

2. Accurate material selection and wide opening. There are red, white and black stones in the mosaic pattern. Some of the same colours also have shades. When selecting materials, it is necessary to select precisely the clear texture, fine grain, pure and uniform color, and no cracks according to the requirements of the drawings. According to the shape and specification of the die, the selected stones are accurately depicted, and the selected parts are cut one by one. When cutting, there should be machining allowance in the periphery, and the pre-width should be 1mm~2mm, so as to prepare for displacement remedy.

3. Careful grinding and grouping. Slowly grind the reserved part of the cut pattern stone to match the connecting line, fix the position with a small amount of adhesive, and then glue one piece by one to form the whole pattern. When bonding, according to the connection of each small pattern, it is divided into several groups. First, it is bonded and bonded from the center, then separately, then it is bonded and bonded with the group, and then it is bonded and bonded with the frame, so that it can be joined in an orderly way, with fast work efficiency, good quality and difficult to move.

4. Colour-mixing and seepage joints, reinforcement by sprinkler net. After the whole pattern is glued together, the color is mixed with epoxy resin, stone powder and colour material. When the colour is similar to that of stone, a small amount of drying agent is added to mix the colour, which quickly penetrates into the gaps connected to each position and scrapes the surface colour material later. Lay the fibre gauze, sprinkle the stone powder with resin, evenly smooth, so that the gauze mesh and the slate are bonded.

5. Grinding and polishing. Place the glued mosaic slab on the grinding table steadily, add grinding smoothly, no sand road, wax polishing.

3. Acceptance criteria for stone patchwork

1. The same kind of stone has the same color, no obvious color difference, color spot, color line defects, and no yin-yang color.

2. The pattern of stone mosaic is basically the same, and there are no cracks on the surface.

3. The error of peripheral dimension, gap and pattern splicing position is less than 1 mm.

4. The flatness error of stone mosaic is less than 1 mm and there is no sand road.

5. The surface gloss of stone patchwork is not less than 80 degrees.

6. The colour of the colour of the colour of the colour of the bonding gap or the colour of the binder used for filling stones should be the same as that of the stone.

7. The diagonal and parallel lines should be straight and parallel. The curves and corners of the arc should not be moved, and the sharp corners should not be blunt.

8. The packing time of stone mosaic products is smooth, and the installation direction indication number is marked, and the qualified label is affixed.

Post time: Oct-10-2019