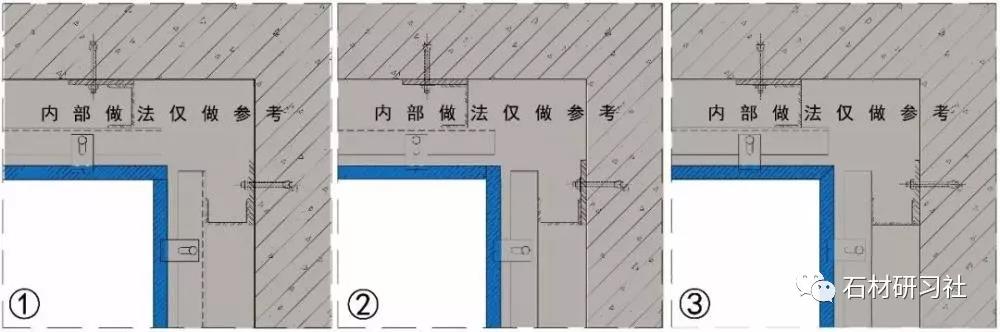

(1) Direct contact

(2) Retaining grooves

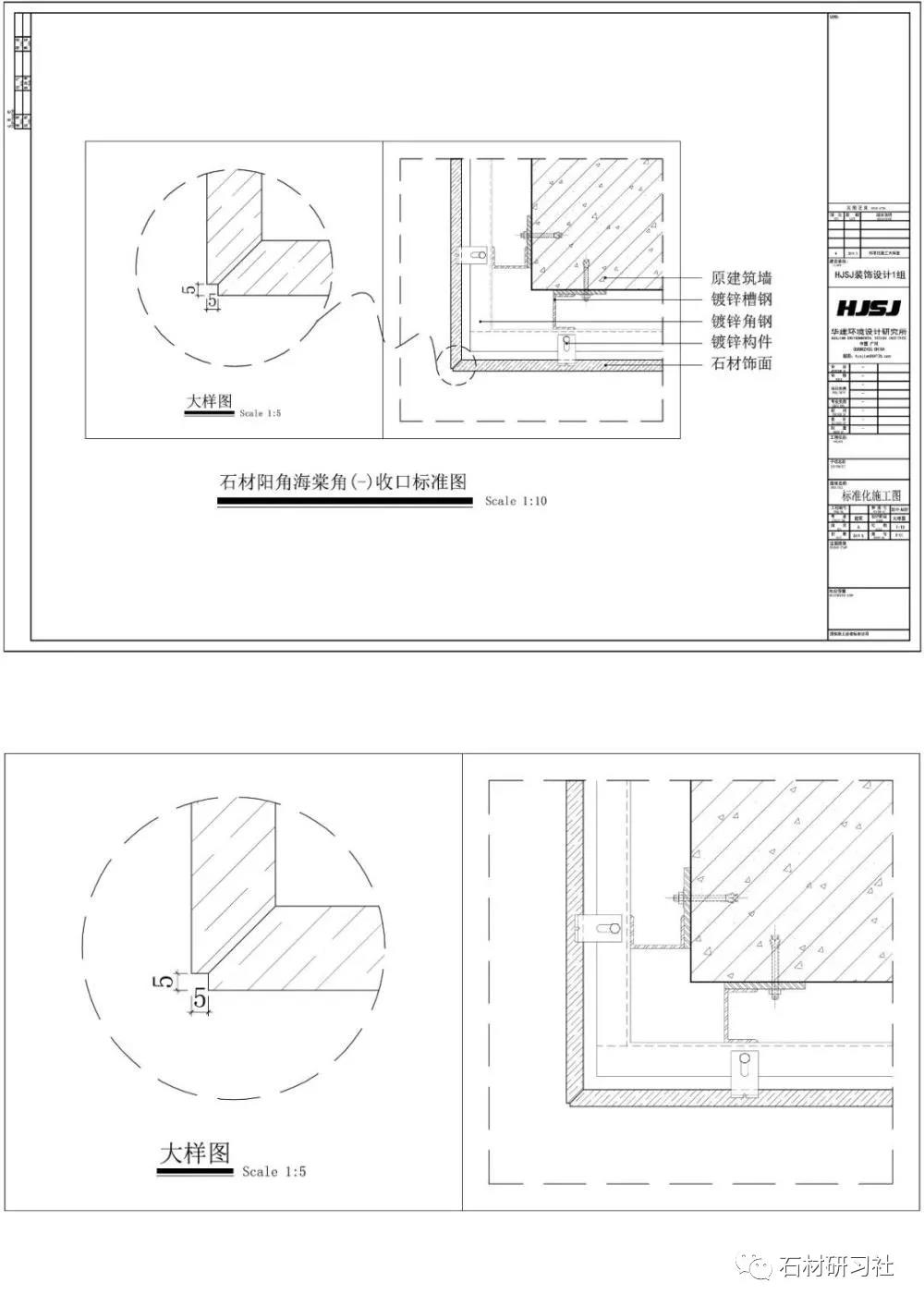

(3) 45 degree oblique spelling

Interpretation of terminology: [Closing] In decoration, “closing” is also called “closing edge”. Professional point is called “handing over relationship processing”. Through the processing of the edge, corner and connecting part of decorative surface, the purpose of making up for the deficiencies of decoration and increasing decorative effect has been achieved. Receiving is the main part of detail engineering in decoration engineering. Whether the closing can be done well is related to the final effect of decoration.

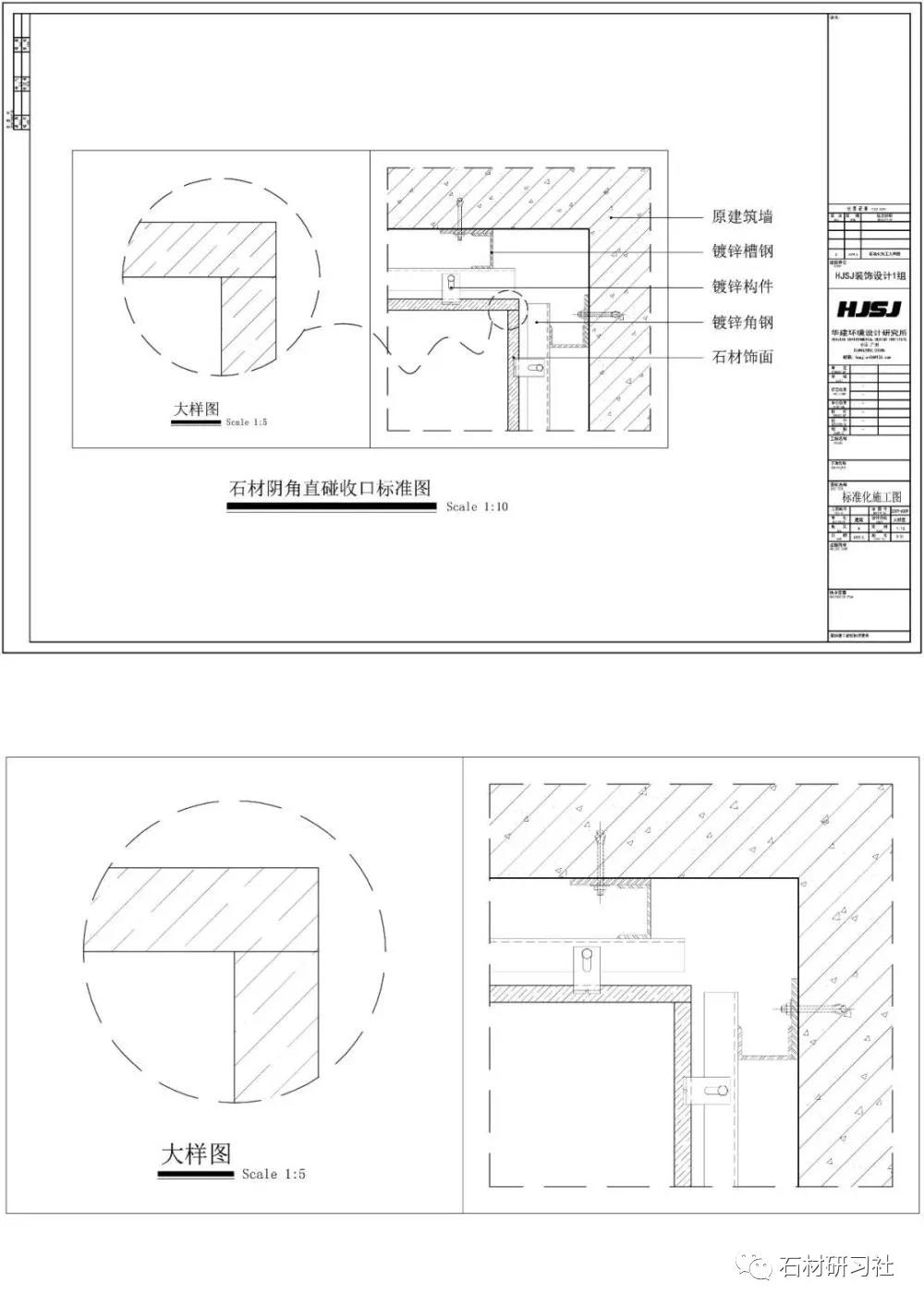

It is undoubtedly the most common shade angle of the wall, because the stone is measured in the unit of “complete block”, and the shade corner of the stone wall (non-ground and wall) adopts the form of “direct contact” closure, which is easy to construct, low material loss, general technical requirements, but also affected by the construction technology, and produces certain visible joints. Gap (negligible, seam treatment).”Direct impact” is suitable for stone and ceramic tile of various profiles. It is a general design and concise design. It is widely used as a closing form for projects with low design requirements.

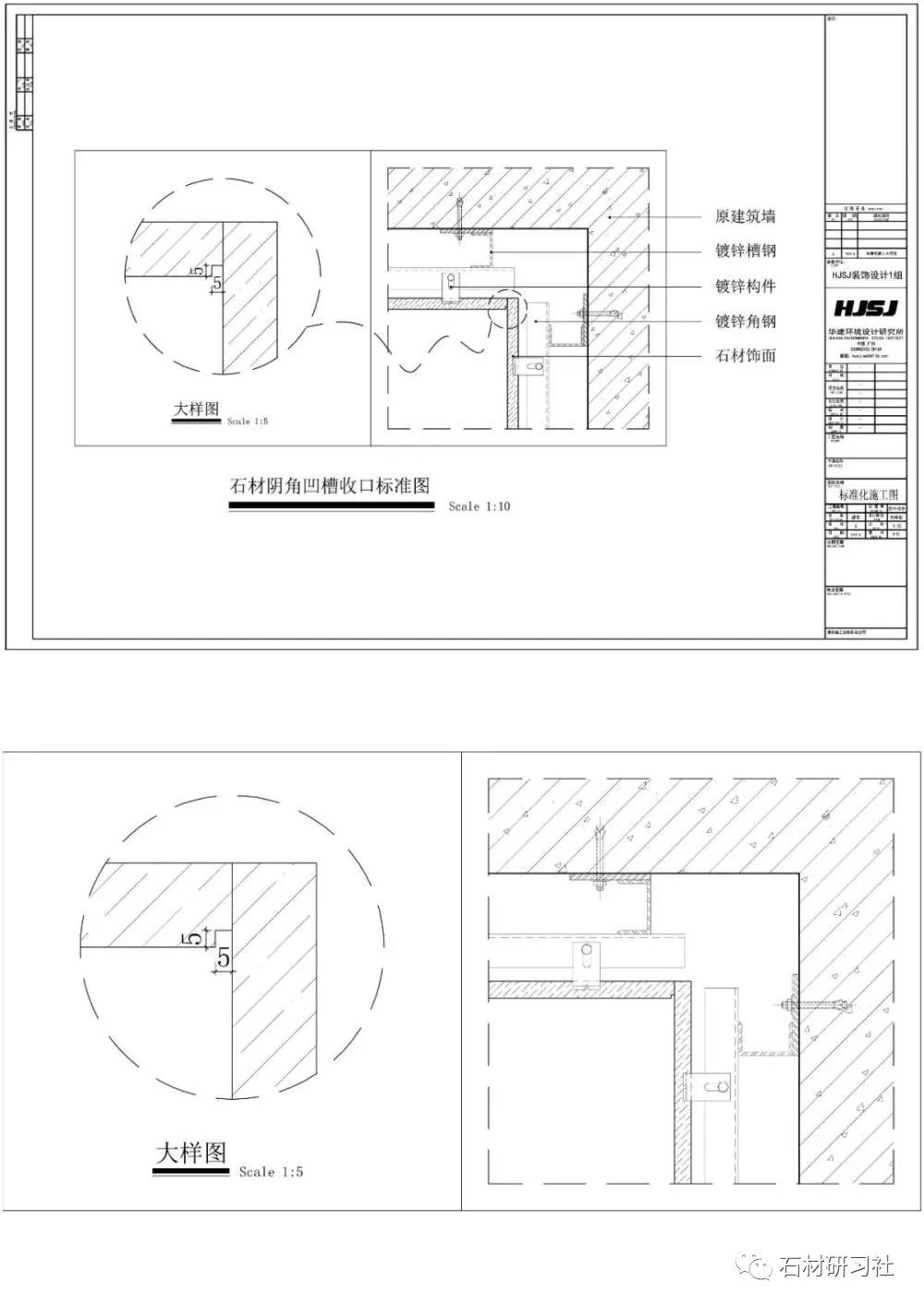

“Retaining groove” means that the “5*5mm process joint” is usually processed at the “butt corner” of a stone or ceramic tile. It can be seen that a “stone edge grinding” process is added, which increases the construction cost, and also damages the integrity of the stone. Some designers still use this “closure form” to achieve better decorative effect. On the one hand, the “concave effect” alleviates the gap exposure between two stones, which affects the beauty. On the other hand, it increases the linear sense of wall modeling, which is suitable for the design of space with certain artistic aesthetic requirements.

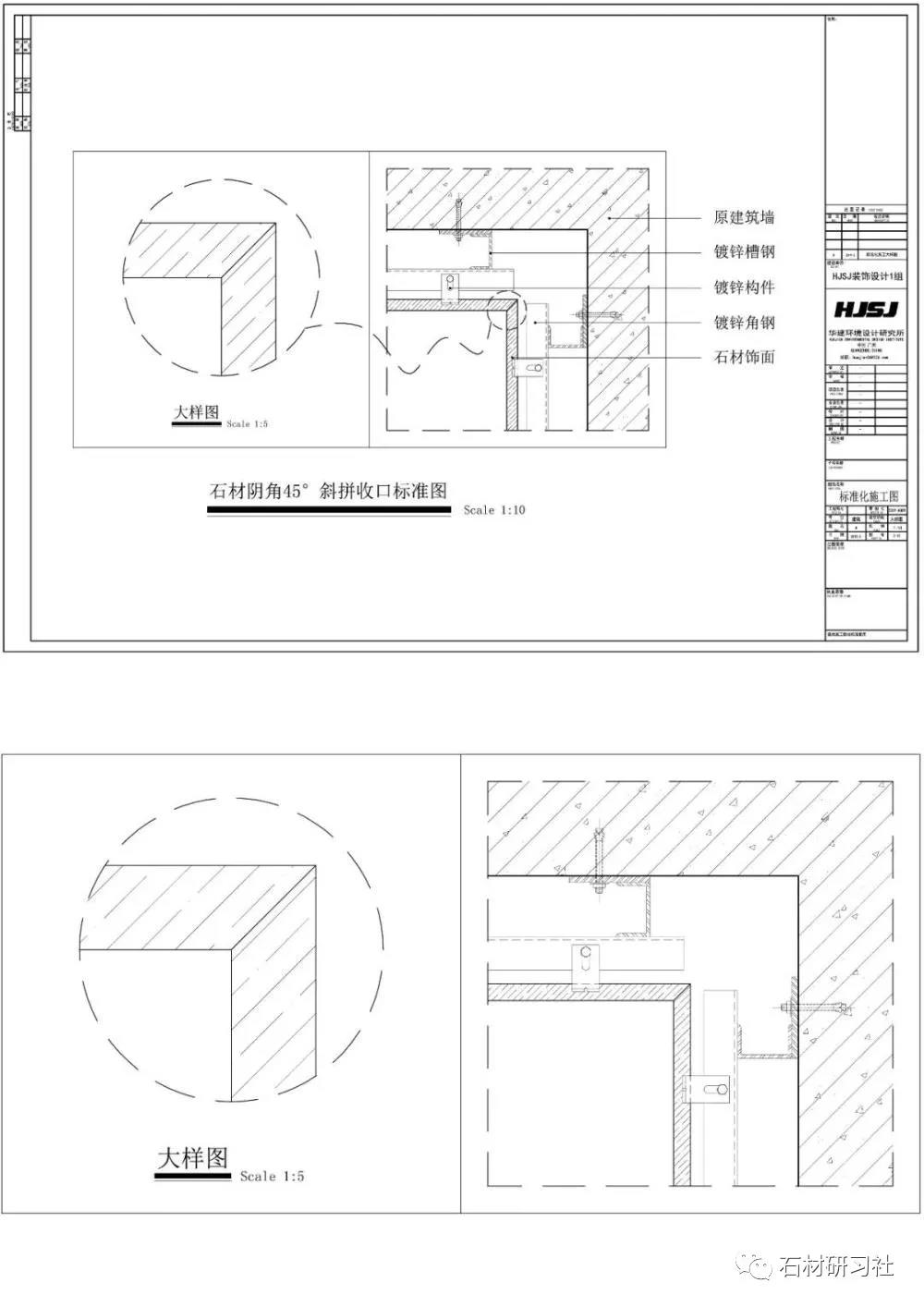

The decorative effect of “45 degree diagonal splicing” is similar to that of “direct collision”, but the difference is that the construction cost and material loss rate are higher than that of “direct collision”. The two jointed stones need to be pre-processed into the diagonal edge of 45 degree angle, which is in accordance with each other. Generally, the negative angle of the wall is not commonly used (the positive angle is mostly common). At the same time, they are vulnerable to certain construction technology or other influences. It will show a certain gap, which will affect the beauty. In order to make up for the shortcomings, we can glue the seam on the basis of “45 degree diagonal assembly” to make the gap more natural and close.

[Analysis]

(1) Technological characteristics: high utilization rate of tradition and the general public

2. Decorative effect: concise and sharp

(3) Applicable parts: Yang Angle and Yin Angle

4. Applicable materials: stone and tile

Construction degree: (Stone is measured by “complete block”. Before dry hanging, two stones need to be “45 degree” grinding bevels. That is to say, there are certain requirements for construction technology. If the treatment is not good, the phenomenon of “angle collapse” will occur. In addition, the integrity of stones will also be damaged.

[Analysis]

(1) Technological characteristics: 45 degree diagonal splicing is widely used and popular.

2. Decorative effect: concise, sharp, concave and convex

(3) Applicable parts: Yangjiao (4). Applicable materials: stone and ceramic tile

(5) Construction degree: (On the basis of grinding the inclined edge of two stones at “45 degrees”, each “butt edge” needs to be inverted “right angle”, so that when two stones are butted at positive angles, a “5*5mm technological groove” commonly known as “Begonia angle” is formed, which has certain requirements for construction technology, in addition, the integrity of stones is also a certain loss. But it improves the phenomenon that 45 degree oblique spelling is prone to “collapse angle” because of its sharpness, and “crabapple angle” is obtuse angle and not easy to break, so designers often use “crabapple angle” as closure treatment.

Note appended:

(1) Size parameters of dry-hanging stones: more than 25 mm

(2) Size parameters of finished surface of dry-hanging stone (stone + base structure): 200mm (commonly used)

(3) Size parameters of stone grooves (process joints): 5*5mm (commonly used), 8*8mm, 10*10mm

(4) The decoration design is huge and complex. Referring to the standardized “basic technology” template, the selection of materials, form, size, base structure, wall type and other aspects should be diversified according to the design scheme/cost/engineering requirements.

Post time: Jun-26-2019