Scope

This atlas introduces the common nodes of the bracket type stone curtain wall and the back bolt type stone curtain wall.

This atlas specifies the general technical requirements for dry hanging stone curtain walls of Shenyang Yuanda Aluminum Industry Group.

This atlas is applicable to the design of stone curtain walls for civil buildings with a height not exceeding 150m, which are not designed for seismic resistance or are designed for seismic resistance of 6-8 degrees.

02

Stone curtain wall

1. Stone curtain wall is a curtain wall made of metal components and stone slabs. It is divided into support slab stone curtain wall and back bolt stone curtain wall according to the connection form of stone slabs and structures. A stone curtain wall connected by a support plate between a stone panel and a structure is called a support plate stone curtain wall. A stone curtain wall connected by anchor bolts between stone panels and structures is called a back bolted stone curtain wall.

2. Granite should be used as outdoor stone, with a silicon dioxide content of over 70%. Other types of rocks are not suitable for outdoor use, and the stone slab area is generally less than 1m2 with a thickness of no less than 25mm.

3.1 The layering and layering of the stone should be reasonably selected based on the bending direction of the stone slab.

The direction of the bending moment on the stone slab is blown straight in accordance with the layering and layering of the stone slab.

3.2 The fire resistance of stone should be above 1500 ℃ without collapse.

3.3 The water absorption performance of stone should be less than 0.8%, and the bending strength design value of stone should not be less than 3.7N/mm2. The same vein stone slab should be used on the same color curtain wall.

3.4 The surface treatment method of stone should be determined based on the environment and use. According to the classification of surface treatment methods, stone is divided into the following three types:

a. Fine faced stone (RB): A flat and smooth sheet material.

b. Mirror stone (RL): A board with a flat surface and a mirror like luster.

c. Rough stone (RU): The surface is flat. Rough board with regular processing stripes, such as machine planing board, chopping axe board, hammering board, and singeing board.

The thickness of fired stone slabs should be 3mm thicker than polished stone slabs to meet the requirements of equal strength calculation.

4. The stone used in stone curtain walls should comply with the provisions of the following current national standards:

JC204

JC205

GB9966.1 Test Methods for Compressive Strength of Natural Decorative Stones after Drying, Water Saturation, and Freezing Thawing Cycles

GB9966.3 Experimental Methods for Natural Decorative Stone, Bending Strength, Density, True Density, True Porosity, and Water Absorption

GB9966.5 Test Methods for Natural Decorative Stone and Wear Resistance

GB9966.6

03

Plank style stone curtain wall

1. Pallet

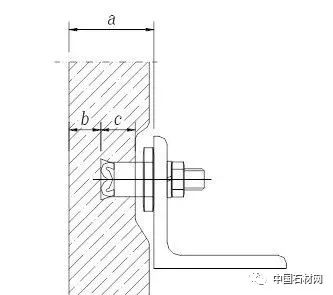

There are two types of materials for pallets, stainless steel and aluminum profiles. Thickness of stainless steel support plate δ≥ 3mm, commonly used stainless steel materials: 0Cr18Ni9, 1Cr18Ni9. Thickness of aluminum profile support plate δ≥ 4mm, material 6063-T5 or 6063-T6 (aluminum support plate material selected based on strength calculation), steel support plate has good strength, and the machining dimensions are not easy to maintain. Aluminum pallets have accurate dimensions and slightly lower manufacturing costs compared to steel pallets. The commonly used pallets are shown in the attached figure.

2. Stone slabs

The color of the outer surface of the stone should meet the design requirements, and the pattern should be checked according to the sample. There should be no obvious differences around the stone. The connection parts of the stone slabs are free from defects such as collapse, hidden cracks, and sanding.

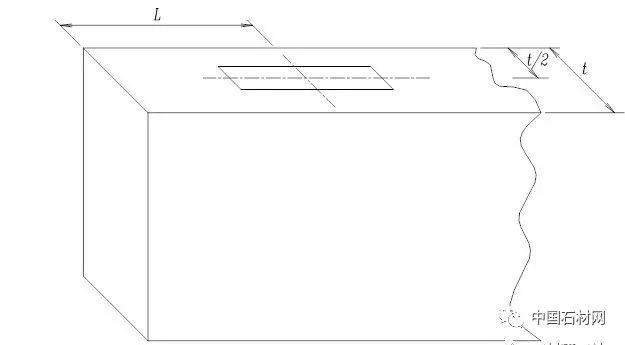

a. Short slot type.

There are two short grooves on both sides of the stone slab, with a length of 100 ± 12mm and a depth of no more than 25mm. The width of the short groove should be 6 ± 1mm or 7 ± 1mm. The processing groove is based on the outer surface of the stone slab, as shown in the following figure:

100 ≤ L ≤ 200, the groove should be polished to a 45 ° chamfer, and the smoothness inside the groove should not be less than 12.5

b. Full length groove type

Long grooves should be opened on both sides of the stone slab, with a width of 6 ± 1mm or 7 ± 1mm, and the groove depth should not exceed 25mm. The processing of the full-length groove is based on the outer standard surface of the stone slab.

The stone slab has a long groove, and the contact area between the support slab and the stone is large. The stress on the slab is good, and it is generally used as a dry hanging method for the upper stone of high-rise buildings. This method has a large amount of stone processing and high manufacturing costs, and is rarely used in engineering except as specified by experts. Short grooves are made in stone slabs, resulting in a small amount of stone processing and lower manufacturing costs. It is commonly used in engineering.

1. Adhesive for stone curtain walls

Common structural adhesives for stone curtain walls include: Hercules marble adhesive, A B glue, SS621

Common weather resistant sealants for stone curtain walls include SS602B and DC791

The upper and lower grooves of the stone slab are filled with structural adhesive, usually using Hercules marble adhesive, which has the advantage of not polluting the stone.

2. The nodes of the supporting stone curtain wall are shown in the attached diagram.

If the on-site conditions permit, the long holes on the angle steel horizontal frame of the supporting stone curtain wall can be changed to round holes and drilled on site.

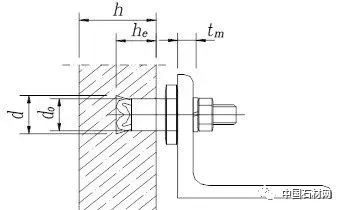

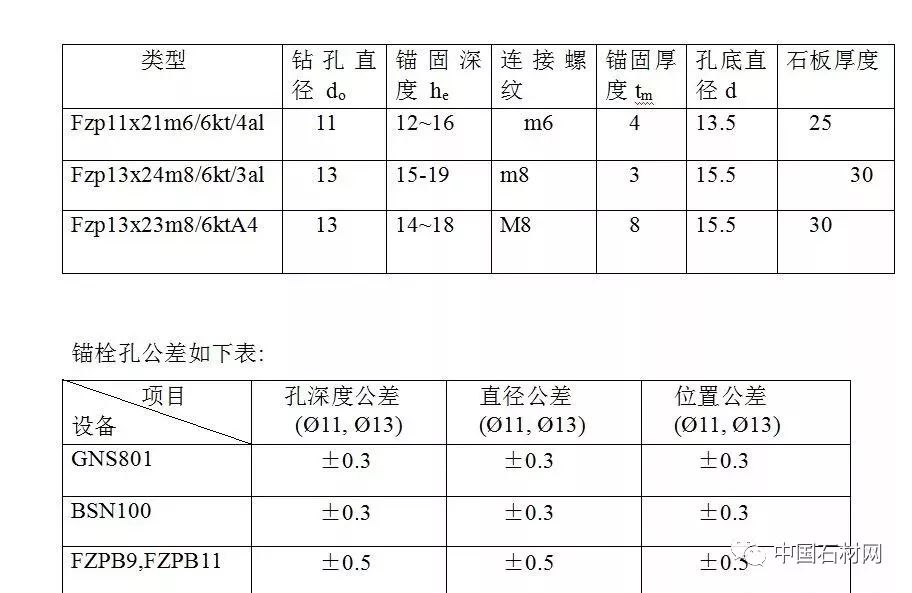

2. Processing and technical requirements for back bolt holes

The processing of back bolt holes must use specialized equipment, and commonly used drilling equipment models include GNS801, BSN100, FZPB9, and FZP11.

a. The fixed drilling equipment GNS801 has high processing accuracy and labor productivity, making it suitable for large-scale production. The hole depth control is based on the outer surface of the stone, and the equipment is not movable.

b. The mobile drilling equipment BSN100 has high processing accuracy and labor productivity, making it suitable for medium batch production. The hole depth control is based on the outer surface of the stone, and the equipment is movable, making processing convenient.

c. The manual drilling tool FZPB9.FZPB11 has low machining accuracy, and hole depth control is guaranteed by the operator. Drilling is convenient and flexible, making it suitable for small batch production.

2. Processing and technical requirements for back bolt holes

The processing of back bolt holes must use specialized equipment, and commonly used drilling equipment models include GNS801, BSN100, FZPB9, and FZP11.

a. The fixed drilling equipment GNS801 has high processing accuracy and labor productivity, making it suitable for large-scale production. The hole depth control is based on the outer surface of the stone, and the equipment is not movable.

b. The mobile drilling equipment BSN100 has high processing accuracy and labor productivity, making it suitable for medium batch production. The hole depth control is based on the outer surface of the stone, and the equipment is movable, making processing convenient.

c. The manual drilling tool FZPB9.FZPB11 has low machining accuracy, and hole depth control is guaranteed by the operator. Drilling is convenient and flexible, making it suitable for small batch production.

05

Principles for selecting stone nodes

1. The selected stone structure form (back bolt type or support plate type) should meet the requirements of the owner or design institute.

2. According to the selection of stone curtain wall nodes for civil engineering structures, the cost of curtain wall production and installation should be minimized as much as possible.

(1) When the civil structure is a shear wall and relatively flat, the stone curtain wall adopts a point method. There are two types of structural forms, the support plate form and the back bolt form. Please refer to this atlas YB-D001~YB-D012.

(2) When the civil engineering structure consists of brick walls and structural columns, the stone curtain wall adopts the method of only horizontal frames without vertical frames. The structural form is shown in this atlas YB-D013~YB-D024.

(3) When the civil structure consists of brick walls and structural columns, but the structural columns are not allowed to bear weight, the stone curtain wall adopts the method of having horizontal and vertical frames. The selection of horizontal and vertical frames should be determined based on strength calculations. The horizontal frame should be placed on the outside of the vertical frame, and an expansion joint should be set every 10 meters between the horizontal frames. The spacing between vertical frames can be arranged without dividing them into panels. The main structural form is shown in this drawing YB – D025-YB-D049.

(4) Replaceable stone curtain wall (for reference only) The node structure of the replaceable stone curtain wall scheme can be found in this atlas (YB-D050~YB-D051), and its application is not limited by the civil engineering structure. The civil engineering structure can be used in the form of shear walls or structural beams and columns. The connection between stone and horizontal frames can be achieved in the point method, horizontal frame method, and horizontal and vertical frame method. Its advantage is that it achieves micro adjustment in the three-dimensional direction of space. There are two forms of connection between the horizontal and vertical frames: welding and bolt connection. Its disadvantages include a large amount of profiles, high material costs, high stone processing accuracy, large processing volume, high processing costs, and on-site installation.

3. The stone nodes and processing drawings in this drawing set are common practices. In actual engineering, the detailed design should be tailored to local conditions, and specific problems should be analyzed.

4. Technical description:

(1) The distance between the stone exterior decoration and the wall is shown in the grid diagram or vertical block diagram.

(2) Connect the corner code to the vertical frame channel steel by welding with J422 welding rod, with a welding length of no less than 150mm.

(3) Fill the gap between the semi-circular grooves of the stone support plate with Hercules marble adhesive.

(4) The number and specifications of support plates are determined based on strength calculations. Generally, stone plates with a width of 1200mm or less are fixed horizontally with two support plates, while stone plates with a width greater than 1200mm are fixed horizontally with three support plates.

06

Comprehensive Economic Analysis

1. There are two types of structural forms for point stone curtain walls: support plate point structure and anchor bolt point structure. These two structural forms are suitable for civil engineering structures that are shear walls and have relatively flat walls. These two structural forms are not applicable to other civil engineering structures. The use of steel for the support plate point structure stone curtain wall is small, the length of steel parts is short, the material utilization rate is high, and the material processing cost is low. The cost of stone curtain wall per square meter is low. The cost can be found in the material cost accounting for the panel point stone curtain wall.

The installation and adjustment of stone panels are very convenient, but the disadvantage is that there is a large amount of expansion bolts. This structure is the preferred method for stone curtain walls. Compared with the panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel panel. The cost of each square meter of stone curtain wall is more than 100 yuan, as shown in the cost calculation of anchor point stone curtain wall. Unless specified by Party A or the design institute, this method is not adopted for stone curtain walls.

2. There are two types of structural forms for horizontal frame stone curtain walls: support plate horizontal frame structure and anchor bolt horizontal frame structure. These two structural forms are suitable for civil engineering structures, which are brick walls and structural columns, and the structural columns can withstand external forces. These two structural forms only have horizontal frames and no vertical frames. The selection of horizontal frames should be determined based on strength calculation. When the wall is uneven, adapters should be used to connect the horizontal frames and structural columns, and the length of the weld seam should be calculated based on strength.

The use of steel for the horizontal frame stone curtain wall with supporting plates is relatively small, resulting in low material processing costs and low material costs. It is difficult to adjust the stone panels up and down, and the on-site installation operation is also difficult. The angle steel of the horizontal frame is equipped with circular holes on site, reducing the processing cost in the factory and the deformation of the horizontal frame. The on-site installation also greatly shortens the time for finding materials. The cost of this structural form can be found in the cost accounting of the horizontal frame stone curtain wall with supporting plates.

Compared with the support plate horizontal frame structure, the anchor bolt horizontal frame structure requires twice as many horizontal frames as the support plate horizontal frame structure. The anchor bolt price is expensive, and special equipment is required for drilling stone slabs, resulting in high processing costs. The cost of stone curtain walls is more than 100 yuan per square meter. Unless otherwise specified by Party A or the design institute, this structural form of stone curtain walls shall not be used. The cost of anchor bolt horizontal frame stone curtain walls is shown in (Cost Accounting).

3. There are two types of stone curtain wall structures: horizontal and vertical frame structures with support plates and anchor bolts. These two structural forms are suitable for civil engineering structures, which are structural beams and structural columns, with no fixed points between the two floors. The selection of horizontal and vertical frames should be determined based on strength calculation. The length of the weld seam should be calculated based on strength and temperature stress should be considered for determination.

The horizontal and vertical frame structure of the stone curtain wall is equipped with round holes on site for the angle steel of the horizontal frame, which reduces the cost of processing in the factory and reduces the deformation of the horizontal frame. The on-site installation also greatly shortens the time for finding materials. It is difficult to adjust the up and down direction of stone slabs, and on-site installation and operation are also difficult. The welding workload between the vertical and horizontal frames of the connectors is large. The cost of this structural form can be found in the cost accounting of the horizontal and vertical frame stone curtain wall with supporting plates.

The amount of anchor bolt horizontal and vertical frame stone curtain wall horizontal frame angle steel is twice the amount of support plate horizontal and vertical frame horizontal frame. The price of anchor bolts is expensive, and the drilling cost of stone panels is high. The cost is shown in (cost accounting for anchor bolt horizontal and vertical frame stone curtain walls), which is more than 110 yuan per square meter higher than the cost of supporting plate horizontal and vertical frame stone curtain walls.

Post time: Apr-08-2024