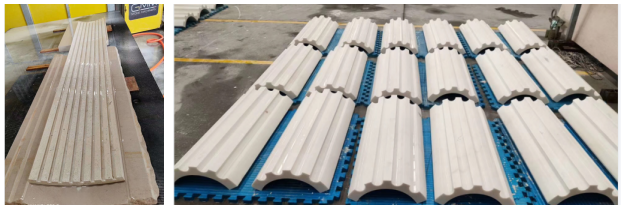

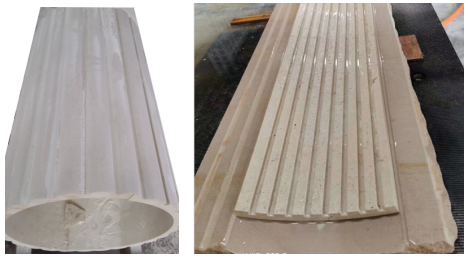

The processing of Roman groove circular arc plates is divided according to the equipment used, including the imitation machine processing of Roman groove circular arc plates, the computer lathe processing of Roman groove circular arc plates, the lathe processing of Roman groove circular arc plates, and the electronic bridge cutting machine processing of Roman groove circular arc plates. The Roman groove circular arc plate has outer and inner arc grooves, as shown in Figure 1 and Figure 2; There are slots along the direction of the busbar and slots along the circular arc surface. Figure 3 shows slots along the direction of the busbar, and Figure 4 shows slots along the circular arc surface.

Process flow for slotting circular arc plates: Production and processing order reading → Incoming inspection → Plate arrangement, color matching, and numbering → Template production → Positioning and molding → Circular arc plate clamping → Machine tool debugging → Drawing lines → Trial processing → Inspection → Batch processing → Inspection → Numbering → Unloading → Splicing and grinding Roman grooves → Polishing Roman grooves → Inspection of Roman grooves on circular arc plates → Trial assembly inspection → Cleaning and protection → Final inspection → Packaging

(1) Before reading the production and processing order for Roman groove slotting, the processing personnel should carefully read the production and processing order in advance to clarify the quantity of circular arc plates that need to be slotted for processing; The processing requirements include whether the product is slotted or non slotted, what type of slot to be slotted, the radius, width, and depth of the slot.

(2) When the incoming material inspection operator receives the incoming material, they inspect the condition of the incoming material before processing: check whether the color and texture of the incoming material meet the requirements; Check the chord length, height, and thickness at the thinnest point. If there are any problems, report them to the workshop manager in a timely manner.

(3) Arrange, color, and number the circular arc plates to be slotted according to the splicing diagram on the production processing order. Adjust the order of arranging the plates when there are differences in color and texture, so that the color and texture of the circular arc plates to be slotted are basically coordinated.

(4) The standard template for making circular arc plate slots is used to verify the accuracy of the Roman groove on the cut circular arc plate.

(5) Positioning molding is used to make a mold on the side of the processing machine, fixing the circular arc plate to be slotted in Rome. Refer to Figures 6 and 7.

(6) The circular arc plate clamp is used to install the circular arc plate of the Roman groove to be processed on the slotting machine. If the height of the circular arc plate is not high during clamping, it can be clamped according to the splicing diagram on the production order, which can ensure that the grooves opened by the circular arc plate are completely spliced together without deviation and with good accuracy.

(7) Machine tool debugging: Some circular arc plates with Roman grooves can be machined with a forming tool. Install the forming tool before debugging the machine tool. Debugging the machine tool, mainly setting the zero point and completing the tool alignment work. When debugging the slotting machine for the circular arc arch shown in Figure 6, align the blade from the centerline of the circular arc plate and adjust the depth of the blade. For the electronic bridge slotting in Figure 7, first draw Autocad, then modify the graphics and convert them into a program for processing. Quickly simulate the machining path before processing, determine the correctness of the program, and ensure that the machining is problem free.

(8) Use a standard slotted template to draw lines tightly against the end face of the circular arc plate, and the width of the lines should not exceed 1mm.

(9) Before batch processing, conduct a trial machining of one piece to determine whether the machine tool debugging meets the requirements. If it does not meet the requirements, identify the problem and re adjust the slotting machine.

(10) Verify the accuracy and shape of the Roman groove using the standard template for Roman groove.

(11) After batch processing and trial processing are qualified, batch processing can be carried out. Figures 6 and 7 show two processing methods for the Roman groove of the circular arc plate. Figure 6 shows the specialized equipment for slotting Roman grooves on circular arc plates, while Figure 7 uses an electronic bridge cutting machine for slotting.

(12) The inspection operator first uses a standard slotting template to self check the slotting accuracy, and then the process product inspector inspects the already slotted arc. After passing the inspection, continue processing.

(13) When the circular arc plates that have already been slotted are removed from the slotting machine, they are numbered according to the processing sequence for easy subsequent processing and splicing. Number according to the arc plate splicing diagram on the production and processing order.

(14) Unloading: Remove the processed Roman groove arc plate from the molding equipment workbench and place it on the product turnover rack. Figure 8 and Figure 9 show the circular arc plate with the Roman groove opened.

(15) Before polishing the processed Roman groove arc plate, the Roman groove should be polished according to the installation drawing, and the joint of the arc plate should be polished. When grinding, it should be noted that the length of the grinding should not be too short, at least 1 meter or more, to ensure smooth straightness of the Roman groove, without obvious bending, and checked with a backing plate. The straightness deviation should be controlled within 1mm. Figure 10 shows the stitching and grinding of Roman groove circular arc plates. (16) The polished Roman groove, which has been repaired, is disassembled and placed on a workbench for water polishing. The polishing of Roman grooves on curved plates is often done manually. According to the line polishing process, use 220 #, 320 #, 400 #, 600 #, 1000 #, 2000 #, and 3000 # polishing water grinding discs in sequence. During the polishing process, some numbers can be selected according to specific circumstances. When polishing Roman grooves on stones with different hardness, it is not advisable to use a grinding disc to polish them. Instead, wrap a wooden stick or stone strip with sandpaper to polish the Roman groove. This way, the polished Roman groove will not produce waves and the polishing effect will be better.

(16) The polished Roman groove, which has been repaired, is disassembled and placed on a workbench for water polishing. The polishing of Roman grooves on curved plates is often done manually. According to the line polishing process, use 220 #, 320 #, 400 #, 600 #, 1000 #, 2000 #, and 3000 # polishing water grinding discs in sequence. During the polishing process, some numbers can be selected according to specific circumstances. When polishing Roman grooves on stones with different hardness, it is not advisable to use a grinding disc to polish them. Instead, wrap a wooden stick or stone strip with sandpaper to polish the Roman groove. This way, the polished Roman groove will not produce waves and the polishing effect will be better.

(16) The inspection of the Roman groove on the arc plate is carried out by the process product inspector on the polished Roman groove arc. Require the width of the Roman groove to be basically consistent, with a straightness deviation within 1mm; Inspect the depth of the Roman groove in the country, with a deviation of within 1mm; The surface of the Roman groove has uniform brightness, no obvious waves, and no scratches or abrasion marks.

(17) The polished Roman groove circular arc plate will be inspected comprehensively according to the plate layout diagram on the production processing sheet.

(18) Trial assembly inspection: Randomly select 1-2 sets of Roman groove circular arc plates to inspect the quality of the polished Roman groove circular arc plates.

(19) Clean and protect the circular arc board of the horse trough, and use appropriate protective agents for protection.

(20) The final inspection is carried out by the product inspection personnel to comprehensively inspect the processed circular arc plate. The inspection items include appearance quality, chord length, height, thinnest thickness, width and depth of the Roman groove, straightness, verticality of the circular arc plate, and luminosity of the circular arc plate.

(21) Packaging: The product packaging personnel shall use foam and wooden case to package the processed arc plate.

Post time: Sep-08-2025